Formic: Automating Abundance

Why Robots are good, actually, and how Formic is accelerating their adoption

Welcome to the 1,977 newly Not Boring people who have joined us since last Monday! If you haven’t subscribed, join 160,388 smart, curious folks by subscribing here:

🎧 For the audio version, listen on Spotify or Apple Podcasts

Today’s Not Boring, the whole thing, is brought to you by… Formic

Formic delivers Robots by the Hour to manufacturers. It’s making small and medium American businesses stronger, fighting inflation, and creating abundance. If you want to help bring about an abundant future — or if you just really want to work with cutting edge robots — good news: Formic is hiring.

Hi friends 👋,

Happy Monday! The Phillies are heading to the World Series. What a way to kick the week into gear. Speaking of kicking things into gear…

If you’ve been reading Not Boring this year, you’ll know that I’ve become obsessed with the idea of abundance. Specifically, I believe that technology can push humanity forward and produce a higher standard of living for everyone. This idea has been the topic of essays like Optimism, Working Harder and Smarter, and The Invisible Hand’s Visible Swarm.

Of course, looking around, it’s hard to get super excited right now. There’s inflation, war, climate change, and looming recession. We have no flying cars. Maybe it’s my optimism speaking, but I firmly believe that the cavalry is coming – in the form of abundant renewable energy, biotech breakthroughs, and much more. I unabashedly root for the Hard Startups building solutions to our biggest challenges.

So when Garry Tan, now the President of Y Combinator, reached out to tell me that there was a founder I had to meet, Saman Farid, who was building a really interesting American manufacturing robotics company called Formic, I jumped at the introduction.

Formic doesn’t make robots. It makes it easy for manufacturers to adopt robots. Given the huge gap between their potential impact and actual deployment, I think it’s the most important part of the stack. If Formic succeeds, we’ll manufacture more, better things, more cheaply, in the US.

This essay is a Sponsored Deep Dive. I haven’t put many of these in the Monday slot, but I think that Formic is a company you need to know about, and that fits so well into Not Boring’s main themes that it deserves to be the main event. You can read more about how I choose which companies to do deep dives on, and how I write them here.

Now throw this on to get in the mood:

And let’s get to it.

Formic: Automating Abundance

The goal is abundance.

We want more and better things, more cheaply. We want those things to be made closer to home. We want less fragile supply chains, so that those things are always available when we need them. We want more good jobs, and more time unlocked to maximize our human potential.

Over the long-term, there are a lot of things we can do to create abundance. Generate clean, cheap, renewable electricity. Improve the education system. Build more houses. Change laws.

In the immediate term, the answer is robots.

No, not those robots, at least not yet. These robots.

Automating parts of the manufacturing process with robots is no longer a sci-fi-ish nice-to-have. With 10.1 million unfilled jobs in America as of August, inflation running rampant, supply chains breaking everywhere, and reshoring of manufacturing, robots are a necessity. As Noah Smith wrote in American workers need lots and lots of robots:

If we really want to change our economy in all the ways we’ve been hoping — reshoring manufacturing from China, securing supply chains, preventing inflationary bottlenecks, and so on — we’re going to need quite a lot of automation. Indeed, if the progressive project is to be revived in America, it will need robots to carry it forward.

Robots also happen to be very good for the businesses that employ them, expanding shifts, reducing turnover hassles, and increasing profits.

It’s hard to think of an industry with stronger tailwinds than robotic automation:

Improving AI/ML. Robots can do more complex things better now than they could just a few years ago, and will continue to improve at a rapid clip from here on out.

Labor Shortages. As of August, the Bureau of Labor Statistics reported that there were 10.1 million unfilled jobs in America, of which about 1.5 million are in manufacturing.

Inflation. Things are getting more expensive across the board, and labor costs are a big piece of the puzzle. According to the BLS, private industry labor costs rose 5.5% over the 12 months ending June 2022, after rising 3.1% in the 12 months prior.

Supply Chains Breaking. Due to a combination of labor shortages, component shortages, shipping, and more, broken supply chains and delayed products are a fact of life in post-COVID America.

Reshoring American Manufacturing. After decades of globalization, America is bringing manufacturing back home. As that plays out, there will be even more jobs that need to be filled (and higher prices at American wages, all else equal).

Rising Geopolitical Tensions. The Biden Administration recently dealt a blow to China’s chip manufacturing efforts, the latest move in an ongoing trade war between the two powers. It’s hard to imagine that China – from whom we bought an all-time high $50 billion worth of goods in August according to the US Census Bureau – won’t retaliate.

There are more. In my piece on Hadrian, we covered the aging manufacturing base, and the fact that the next generation either can’t or doesn’t want to take over the family business. Thanks to a cocktail of COVID and politics, US immigration has been declining since a peak in early 2016.

All to say, robots are no longer some futuristic technology that only automakers and avant garde companies like Amazon can afford to play with. Robots are a necessity if we want to maintain our standard of living, and do so at affordable prices.

It’s not (or shouldn’t be) controversial to suggest that we’re going to need, and get, a lot more robots in the coming years. Manufacturing Digital projects that the manufacturing robotics market will more than double from $24.3 billion in 2022 to $52.8 billion in 2026.

The big strategic question is: what’s the best way to ride those tailwinds and accelerate deployment?

One way is direct: make the thing. In this case, make robots. A flood of companies are building robots with all sorts of capabilities, and driving quality up and hardware prices down.

A second is to sell picks & shovels. Make the things that go into making the robots. From software to fixturing to vision systems, startups and incumbents alike are creating new inputs, again improving quality and lowering costs.

A third way is to sit on top of all of the hustle and bustle and competition below, to abstract all of that complexity away and just give customers exactly what they want, wrapped in a bow: as-a-service.

Formic is taking the third path, delivering Robots by the Hour to customers who don’t care who makes the robot or how, just that the job gets done well. Their customers don’t even want robots, really, they want reliable labor. That’s what Formic gives them.

The model, and the company, is the brainchild of Saman Farid and Misa Ilkhechi. Misa’s LinkedIn model puts the societal value proposition clearly: Robots = Unlimited Labor.

Saman grew up in factories after his dad moved the family to Beijing when he was six-years-old. After an Engineering degree from The Cooper Union, Saman got his MBA from a joint program between MIT and China’s Tsinghua University. He’s spent most of his professional life building and investing at the intersection of AI/ML and the real world.

Garry Tan, the Y Combinator President who led Formic’s Seed round while at Initialized Capital, explained how Saman’s background led to Formic:

Saman is a very special example of someone who has seen things most people don't see, and then has followed his intuition to figure out what society, at many levels, needs. His experience with China is relevant, since American vibrance is predicated on strong manufacturing, and automation is the keystone to that.

Specifically, he saw what embracing automation could do to boost an economy. “In China from the 1980s to the 2000s, I saw the impact of rapid and massive industrialization. When I moved to the US, I saw the same thing happening in reverse: legacy institutions, particularly industrial ones, were starting to crumble.”

As an investor at Baidu Ventures, and a board member at multiple robotics companies, he saw first-hand that robotic automation was a thing, that the technology works, and that robots have a great ROI. He also saw that no one outside of Silicon Valley and Detroit was deploying them.

Formic was born to address that deployment gap. It’s not building a new, technically superior robot – there are plenty of brilliant minds working on those, and competitive dynamics are quickly commoditizing that layer – but a suite of software, financial products, and services designed to get all of those robots deployed en masse. Saman told me that Formic wants to “build the world’s largest robotic workforce.”

It’s early, but the model is working. Founded in 2020 and launched in August 2021, Formic has 50+ robots in various stages of deployment, and has grown its revenue 12x year-over-year. For a sense of scale, the largest purchasers in the country buy about 250-300 robots. One more 12x and they’re buying more robots than anyone.

Importantly, Formic is doing more than riding tailwinds; it’s expanding the market. Manufacturers that wouldn’t have deployed robots before Formic are finally automating because the company exists. Formic’s customers include companies that make metal parts for car chassis, aluminum parts for planes, chocolate chip cookies, shredded lettuce that ends up in KFC / Taco Bell, plastic parts for lawn mowers and golf carts, Matcha and protein powder, and spare parts for agricultural equipment. One customer, Polar, has been around so long that it used to make parts for the Ford Model T. The list demonstrates both the breadth of the robots’ capabilities and Formic’s focus on a few beachhead categories, which we’ll explore.

And Formic is well-capitalized to expand. In March 2021, Tan’s Initialized Capital led a $5.5 million Seed round. In January 2022, Lux Capital’s Shahin Farschi led a $26.5 million Series A. In between, the company put in place $150 million of debt facilities, a critical component of Formic’s business model, to fund expansion.

We’ll go into that business model, and much more, to unpack automation and Formic’s role in the ecosystem:

The Rise of the Robots

Formic: Unlimited-Labor-as-a-Service

Formic’s Business Model

Robotic Powers

Automating Abundance

But first, a little bit more on the robots. To root for Formic as hard as you should, you need to understand why more robots = unequivocally good.

The Rise of the Robots

Humans worry about the damndest things.

Thomas Malthus is the all-time example here. Worried that a growing population would overwhelm the planet’s resources and ability to feed us, he argued that humanity needed “religious orthodoxy, political monarchy, and familial patriarchy” to keep our nearly irresistible sexuality at bay or face starvation.

Over 200 years later, with a global population eight times larger than during Malthus’ time, fewer than ten people out of every one hundred live in extreme poverty versus over ninety out of one hundred back then. Malnourishment is still an issue for the world’s extreme poor, but in the developing world, obesity is a much larger threat.

What happened? Did Malthus convince women to abstain from unsanctioned sex? No. The Haber-Bosch process, developed by German scientists by those names in the early 20th century, gave humans the ability to pull nitrogen from the air and produce ammonia at industrial scale. We used ammonia to make fertilizer and improve crop yields. Instead of shrinking the population, we made more food.

Of course, fertilizer wasn’t the only innovation on the farm. New machines – the gas-powered tractor, the steam-powered wheat thresher, and more modern ones – enhanced farmers’ capabilities so greatly that agriculture employment dropped from 84% of the workforce in 1810 to less than 1% of the workforce today, while the US population grew over 50x. People were worried about the loss of farming jobs and power back then – see: Farm Unrest – but people left the farms and found new, less backbreaking jobs. They could buy food with plenty left over for other things when they didn’t need to spend all day growing it themselves.

History is littered with similar examples. Some particularly optimistic folks even believe that in a century, the real challenge with CO2 is that we won’t have enough of it. Turns out it’s really hard to make predictions with complex adaptive systems, “especially about the future.”

Robots are a modern instantiation of this same fear, caused by our very human ability to see the known bad things but not the unknown good things that come with any change. Noah Smith again:

For about five years now, I’ve been seeing people argue that vast numbers of American workers are on the verge of being automated out of a job. Bill Gates suggested a tax on robots to prevent this from occurring. Other tech figures also worried, but went with UBI as their preferred solution. It’s not just tech magnates, though — the economists Daron Acemoglu and Pascual Restrepo have been writing quite a lot of research papers warning of danger from automation. And many research reports from think tanks and corporations over the years have warned that a huge percentage of American jobs are at risk of automation.

Part of the fear is caused by misunderstanding what these robots are. Remember, the robots we’re talking about don’t look like this:

They look like this:

And this:

They’re more machine-like than human-like, and they typically do very specific jobs, often ones that humans don’t particularly want to do: filling boxes, lifting them onto pallets, loading parts into a machine, or screwing caps on bottles. Many of these jobs are so hard on bodies that factories need to shift what workers are doing every few hours to lower the chance of repetitive stress injuries.

Beyond the pictures, the facts don’t support the fears. As mentioned earlier, there is a drastic labor shortage in the US, it’s contributing to delays and inflation, and it’s going to get worse as we reshore more manufacturing. Turns out, we don’t need to worry about the robots taking our jobs; we need to worry about not getting robots deployed quickly enough to keep manufacturers in business and the economy humming.

As part of my research, I looked up Formic on Tegus (yup, that Tegus), and found an enlightening conversation with the CEO of one of its customers, Thomson Plastics. He summarized the situation on the ground better than I can:

But with freight containers at $29,000 versus $5,000, the reshoring that we've talked about for 10 years is actually, physically happening right now. The real tragedy in all this is if that reshoring opportunity presents itself and we as American middle market manufacturing can handle the load, and we can, but it's going to take the proliferation of automation not to replace bodies, but to free up bodies to get the work done and continue to grow. And it's real this time.

The external factors are going to force this up our throat or up to our eyes any way you want to look at it. It's coming. We just accept the fact, prepare, and execute. So once I get this going, I got to find a way to get some money in play with Formic because they're going to be an everywhere name in a very short period of time.

It’s always a good sign when customers want to invest in the company, but the larger point is that the person making the hiring decisions doesn’t view automation as a way to replace workers, but to free them up to do higher value work. Despite the fear around robots, the stats back up this point.

You should read the Noah Smith article if you want all of the charts, figures, and research, but my takeaways are this.

Countries, like South Korea, Singapore, Japan, and Germany, that employ the most industrial robots actually put more people to work in manufacturing than the US.

A series of studies found that “robots are correlated with – and probably cause – higher employment in countries where they’re adopted.”

A 2022 review paper found that while automation does replace jobs, the “reinstatement effect” – people finding new, often better, jobs to do – outweighs job losses.

All of that is a bit counterintuitive. Robots clearly take some jobs, but somehow, that leads to more and better jobs for humans. What’s going on?

Here, it’s useful to understand how a factory works, at the very highest level.

A manufacturer who wants to set up a new factory to make a widget faces four main costs:

Lease: It costs money every month to lease the industrial space for the factory from the landlord, whether the factory is operating or not.

CapEx: Once they have the space, the manufacturer needs to pay to outfit the space to do the job. That might mean construction to alter the layout of the space, and it definitely means purchasing and installing all of the machines needed to make widgets. Some of this can be financed, but much of it is cold hard cash upfront.

Labor: The manufacturer needs to hire people to operate the machines, pack the boxes, load the pallets, and do all of the things needed to make widgets. Unlike the first two cost categories, labor costs are mostly variable and are based on things like how many shifts the factory runs.

Materials: The manufacturer needs to buy the raw materials, like metals, plastics, and rubbers, that they use to make the widgets. This cost, too, is variable based on demand.

The name of the game is to produce widgets with gross margins thin enough to be competitive to potential customers, but thick enough to pay workers and rent and generate a return on the investments (ROI) in machinery and equipment they made upfront. Many small and mid-sized manufacturers generate enough cash flow to pay the bills, but not to continue investing in upgrades or make big bets. Many run one or two shifts instead of the maximum possible three shifts because of labor shortages and the fact that it’s harder to hire people to work overnight. A typical factory runs 2,000 out of a possible 8,700 hours per year.

Manufacturing is a hard business, made harder by labor shortages. As one of Formic’s customers, Polar, put it, “If Polar didn’t automate, we would be out of business. We cannot compete if we cannot produce.”

So how does robotic automation help? It’s not about cutting costs. It’s about running at capacity, growing the top line, and dramatically improving the bottom line.

First and foremost, robots fill the 20-30% staffing shortfall experienced by practically every factory in the US, meaning that they can run at full capacity during shifts. And it can fill those slots with “labor” that costs roughly half as much per hour, improving margins.

More transformationally, robots can increase the factory’s output by 3-4x by allowing them to run more shifts, and run more efficiently during those shifts. Humans who were doing painful, monotonous work like screwing caps onto lotion bottles, pausing to shake out their sore hands after every couple caps, can move up to overseeing the work of a robotic arm.

Because so much of a factory’s costs are fixed, more capacity, as long as it’s met with demand (which, in this market, it likely will be) means higher profits. Rent stays the same. The upfront money for machines is already spent. Labor costs increase in line with demand. And materials costs increase with demand, but decrease on a per unit basis with larger orders.

To see how huge this is, let’s run some purely illustrative and probably wrong but directionally correct numbers on a factory that increases its output by 3x:

Even assuming no cost savings from robotic labor (we make up for it with higher human salaries), a 3x increase in revenue translates to a 25x increase in profit.

With those profits, factory owners can afford to do all sorts of things, like pay higher wages to stand out in a competitive labor marketplace, expand the existing factory or open new factories, which creates more jobs, or lower the prices of their products – the ultimate deflationary force. And, of course, they can invest in more automation, which keeps the virtuous cycle spinning and makes American manufacturing more competitive with foreign manufacturing, brings more jobs home, makes those jobs better for humans, strengthens supply chains, and contributes to that abundant future we all want.

The fear of robots comes from a scarcity mindset – there are only x jobs, and every robot means x-1 jobs for humans. But that’s the wrong way of thinking about the situation. We use technology to automate away our shittiest, least human jobs, and in the process, create more, better, and more fulfilling jobs elsewhere. Just like we figured out how to grow more food. Just like I’m getting paid to sit in an air conditioned room and write about robots instead of working on a farm. And just like, when AI takes my writing job, I’ll find something even better to do.

Formic: Unlimited-Labor-as-a-Service

So we need more robots. The good news is: lots of companies are making them. The bad news is: not a lot of manufacturers are adopting them.

Certainly, demand for robots is growing. According to the International Federation of Robotics, US robot installations grew by 14% in 2021, to 34,987. But that’s peanuts. There are 13 million manufacturing jobs in the US meaning robot installs equaled just 0.27% of manufacturing headcount last year.

If robots are good – reliable, work longer hours, improve work conditions and pay for humans – why aren’t manufacturers adding as many robots to their factories as they can get their hands on?

One reason is cost. While robots pay themselves back fairly quickly, they require large CapEx investments from businesses that operate on thin margins and typically don’t have a lot of cash lying around. The model above assumed a Formic model – rent robots by the hour – but the reality has been that manufacturers need to pay $150-250k upfront per robot.

Another is confusion. OK, role play. Let’s say you run a factory and you heard from your friend at another factory that you should install robots. “They’re great!” he says, “here, take a look.” And he hands you this:

Where do you even begin? If you need a simple Piece Picking Robot, there are eleven companies to choose from, not to mention the 77 Material Handling Solution Providers. You want everything to be automated – does that come with the robots, or do you need to choose from among the 25 Autonomy Solution Providers. How do you install it? What happens if it breaks?

A third is time. The average deployment time for a robot is around 35 weeks.

A fourth is maintenance. Most factories don’t have people on-site who know how to program and fix robots if things go wrong, or reprogram the robots when they need to run new parts. They can pay to train workers, but then those workers become a lot more valuable. The Thomson Plastics CEO described the problem vividly, “Suddenly, even guys that I had trained in-house and had sent to classes and paid for certifications and all this. These guys were jumping ship and leaving us being paid 2 and 3x the hourly rates that we were paying them.”

A final is commitment. Some factories make the same things for a very long time, others shift every few years as market demands change. It’s tough to justify spending the time and money on a robot that might not make sense for your factory in two years. Is there a robot resale market?

Saman had heard all of these concerns firsthand when he talked to his portfolio companies and their customers. The technology was amazing, and it really could improve manufacturers’ businesses, but it wasn’t worth the time, money, or hassle when there were a million other things to worry about, so the buy decision kept getting pushed down the road.

So in early 2020, while manufacturing was shutting down globally, Saman decided to leave the cozy investing life to jump into the fray and build a solution to all of those challenges. Formic was born.

As Garry Tan, who led Formic’s Seed while at Initialized, told me:

Saman is quite special since he has deep experience as an investor in AI and Robotics, and I think it was very interesting how after seeing the difficulties of go-to-market up close, he decided that was one of the most important things to really nail. That all the advanced technology in the world wouldn't make a difference without seeing it deployed in the real world driving real IRR.

Saman’s main insight behind Formic, gleaned from firsthand experience, is that customers don’t necessarily want robots, they want productivity. And they don’t want to pay up front and deal with complexity and setup and maintenance and risk. They want to pay robots like they pay people: by the hour, for work completed.

This is classic Clayton Christensen Jobs to Be Done. In fact, the late HBS Professor’s most frequently cited quote on the topic refers to manufacturing:

People don’t want to buy a quarter-inch drill. They want a quarter-inch hole! People buy products and services to get a job done.

That maps one-to-one with Formic’s thesis: customers don’t want a pallet-loading robot. They want a box loaded onto a pallet!

And Formic’s customers’ customers really don’t care who loaded the pallet. As the CEO at Thomson Plastics said in an expert call with Tegus, “Quite honestly, my customer doesn't give two shifts [sic] how I get part out of the machine. They don't care.”

So Formic doesn’t compete on shiny tech, or the fanciest specs. They compete by giving customers access to reliable, affordable labor by the hour, so that they can give their customers reliable, affordable products by the truckload.

Formic wasn’t the first company to rent robots by the hour. The CapEx pain point was an obvious hindrance to robotics adoption. The challenge was, the other companies that rented robots were the same companies that made them, the OEMs (Original Equipment Manufacturer). While it makes sense for OEMs to provide various financing options, and to facilitate adoption of their products, there are challenges with that model.

First, in a world in which dozens of robotics OEMs exist, each OEM can only offer customers a fraction of the available options, the ones they make, not necessarily the best for the job at hand.

So a company like FANUC might finance their robots, but they only offer FANUC robots - not the grippers, conveyors, sensors or safety systems you need to make the robot useful. Another impressive well-funded startup in the space, Rapid Robotics, has a model that looks similar to Formic’s, but Rapid produces its own robot work-cell that it customizes per job.

Second, making robots and providing all of the software and services associated with delivering productivity are two very different skill sets.

Saman points to the difference between Boeing and United Airlines to drive this point home. The two companies actually started out as one, but split in the face of regulation around government mail contracts. Today, it seems unthinkable that an airplane manufacturer would also run an airline. Making airplanes requires skill in supply chain, manufacturing, B2B and government sales, and a host of other more industrial capabilities. Running an airline requires scheduling, fleet management, customer service, consumer marketing, loyalty programs, and a bunch of other more consumer-facing capabilities. Better to let airlines buy airplanes from manufacturers.

The same is true in practically every industry. John Deere doesn’t run farms. Caterpillar doesn’t run mines. Dell doesn’t run data-centers. Lockheed Martin doesn’t fight wars.

Instead, Formic is able to ride the wave of innovation, competition, and cost declines in robotics by purchasing robots from whichever OEM’s machines do particular jobs best – Saman calls the ability to identify and select the best providers a necessary core competency. In fact, just two years old, the company is on pace to become the largest purchaser of robots in the US. Big buyers like GM and Procter & Gamble buy roughly 300 robots, a pace Formic hopes to surpass by as early as next year.

Formic’s magic comes from doing all of the other things that customers need in order to produce: design, installation, financing, and maintenance. It “automates the process of automating.”

To deliver reliable Robots by the Hour, Formic weaves together a bunch of core competencies into one neat as-a-service package.

Formic builds software to scope, design, and deploy robots at scale. Customers just need to describe their needs and take a LIDAR scan of their space with their phones, and Formic can use its software to run through thousands of possible configurations. This is typically the hardest part of automating – buying a robot arm is the easy part – building the fixturing, vision systems, gripper, electrical & pneumatic systems etc. is by far the most complicated and time-consuming part. Pre-Formic, about 50% of the cost of a deployment was in custom engineering and design work. Formic’s software and templated designs are cutting more and more of that cost, and help the company deploy robots in as little as two weeks instead of thirty-five.

When Saman and I spoke a couple weeks ago, he was buzzing because they’d just completed an install in which Formic showed up with a robot one morning two weeks after the customer signed, and got it running by that afternoon, producing 12,000 parts in its first (half) day at work.

It customizes robots for specific customer needs. Formic buys robots from OEMs – at a lower cost than customers could directly because of its scale – and then uses its software to design customizations and create specs. A customer might need a specific gripper to pick up a certain product, for example. Then Formic works with its network of subcontractors and integrators to build the required workcell to spec.

It builds software to manage and maintain robots remotely. If there’s an issue with a robot, Formic can often diagnose the issue and send a fix without stepping foot on-site (although it has people in each region and integrator partners who can get in the factory when needed). It can teleoperate robots from the comfort of a computer screen. And it can proactively predict when a robot will need maintenance, helping factories maintain crucially important uptime.

It builds software that makes robots more adaptable, leaning on advances in the application of AI to robotics to upgrade robots from afar, a la Tesla, and can modify robots on-site to adjust them to new customer needs.

And it’s incentivized to make sure that its robots are running, and running well, because Formic only gets paid when its robots are working. As Thomson Plastics’ CEO put it:

But the fact that this is monitored equipment and if the machine is down, they don't get to charge me then suddenly, a lightbulb came on for me.

So they've got skin in the game, too. It's not going to be good for their billing as well to allow this stuff to sit down for hours or days or certainly weeks. They're going to us to get their own tech in here and get this stuff back up and running.

Skin in the game is a key feature of Formic’s value proposition, and its business model.

Formic’s Business Model

If Formic is taking on all of the upfront spend, plus the cost to design and customize, and then taking on risk if the robots don’t work, how does it make money? On its face, it seems like a cash flow nightmare.

But Formic is cash flow positive on each of its deals from day one. How?

The best way to think of Formic’s business is that it borrows money at x% and lends it at y%.

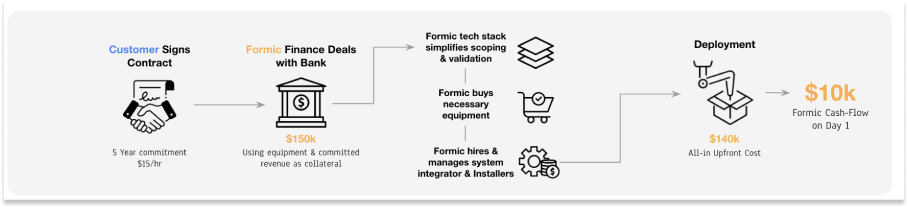

Customers sign five-year contracts and Formic brings those to the banks to borrow money against the contract and equipment it will purchase. It uses the money it borrows to pay for its purchases, upfront costs, and contractors, with some money left over.

From there, as its customers pay Formic for every hour that the robot is in use, Formic pays for service and maintenance, and pays back the loan with the balance.

After it’s repaid the loan, Formic keeps the hourly payments from customers as margins. Assuming the made up numbers from the example – $15/hr, $150k loan – and adding in 5% interest and 10% ongoing service and maintenance costs, it would take Formic roughly two years to pay back the loan at full capacity, leaving three years of practically pure margin. Customers can also extend contracts or Formic can put the robot somewhere else after the contract ends. In either case, Formic continues to generate value from the now wholly-owned robots, adding another worker to its workforce.

As Formic scales, it’s getting faster, smarter, and more efficient, often by identifying and incorporating the best technology that other people build.

For example, it doesn’t need to build the model that powers its simulations. It builds on NVIDIA’s Isaac simulation software and other advanced tools, stitching them together to create systems that turn pictures and questionnaires into simulations and diagrams. Instead of building robots from scratch, it parameterizes components and builds standard templates for tasks, slowly reducing the need for one-off customizations over time.

Today, it keeps its focus narrow, optimizing for speed and reliability. Its robots do five main things very well: palletizing, case packing, welding, machine tending, and injection molding.

Its go-to-market (GTM) is focused on three big categories of customers for whom those five uses are critically important: consumer packaged goods (CPG), metal parts, and plastic injection molders.

Every factory has five to ten jobs that fit the Formic model perfectly, and a dozen others that the model is flexible enough to accommodate. For more complex jobs, it works with systems integrators to deliver solutions. Today, most of the robots it deploys are first wave (old school rule followers) or second wave (rule-based with “some perception, but dumb perception”). The third wave, AI-driven tools, will swap out sensors for cameras and use software to interpret and adjust in real-time, expanding the use cases that can be served out of the box. “A bunch of people are working on it and building cool things,” Saman told me, “but they’re not ready for industrial use. They’re at 85-90% uptime; they need to be at 99.999%.”

The beauty of Formic’s model is that when the third wave robots are ready, Formic will be ready for them, without needing to spend hundreds of millions of dollars or burning customer trust in the process.

Of course, things could go wrong.

The biggest challenge right now is getting components for customizations. Until Formic helps fix the supply chain issues, they have to sit on the other end of those issues, waiting for parts held up in someone else’s supply chain. That slows down time to deployment, revenue, and cash flow.

Once deployed, a factory could keep running only one shift, leading to lower utilization and less revenue. Contracts have minimum hours baked in – $75k per year in the example - but only hitting the minimum would lower margins. Formic is also fully on the hook if things break and stop working.

Rising interest rates will also put pressure on margins. Formic was born in the ZIRP era, which made the “borrow at x%, lend at y%” trade particularly juicy. That said, because of all of the value that Formic adds on top of just financing, and because of how quickly its costs are dropping due to scale, the margin is wide and we’d have to see Paul Volcker reincarnated for it to close.

Finally, the model is so good when it works that there’s bound to be competition. The most direct competition seems to be from Rapid Robotics, but others are likely to enter the space given the size of the prize and the economics of the business. Just as with human labor, a glut in supply could lead to pressure on “wages.”

That said, Formic has a big head start on would-be competitors and is building moats around the business. That’s right, ladies and gentlemen, it’s 7 Powers time.

Robotic Powers

As a reminder, 7 Powers is a book by Hamilton Helmer and one of the most useful strategy books ever written. In it, Helmer identifies and explains the seven types of moats that companies can build. I like Flo Crivello’s succinct definition of moats: “Moats are those barriers that protect your business’ margins from the erosive forces of competition.”

Assuming that there will undoubtedly be competition in the robots-as-a-service space, which forces will protect Formic’s margins?

I could make an argument that, at various points, Formic will leverage five of the powers.

In the early days, it’s counter-positioning against incumbent OEMs by doing something that they can’t – offering the best robots, and fully integrated solutions, across multiple OEMs. Given that this won’t protect them from copycat competitors, we won’t focus here.

Once it works with enough customers, there will be high switching costs. Ripping robots out from the manufacturing process once they’re in could delay production for days at best and months at worst, something manufacturers can’t afford to do. Given that the vast majority of potential customers are yet to adopt robotic automation, with Formic or elsewhere, we won’t focus here, either.

Instead, we’ll focus on the three that I think will protect Formic’s margins over the long-term: economies of scale, brand, and process power.

Economies of Scale

Scale Economies, or Economies of Scale, is the classic power, particularly in industrials: “The quality of declining unit costs with increased business size.”

Buy more of something, get bulk discounts, lower prices, increase demand, get bigger discounts, and so on. With enough scale, it becomes practically impossible for competitors to compete on price. Think Walmart.

Formic can benefit from economies of scale in two categories: robots and financing.

The first one – robots – is obvious. Formic’s goal is to build the world’s largest robotic workforce, and it’s already on a path to become the largest buyer of robots in the world in the next few years. When that happens, it will also be the largest buyer of many of the custom parts used for specific jobs. In fact, with enough customers, it will reach a scale at which it should be able to standardize and mass produce many of those now-custom parts.

The second one – financing – is less obvious but also important. As Formic borrows and repays more money, and builds a track record with banks, it should be able to further lower its cost of capital relative to both customers and competitors. In such a CapEx-heavy business, lower financing costs is an enormous competitive advantage.

In both cases, as Formic achieves its growth objectives, it will be able to pass savings on to customers, or reinvest margins in team and technology, and make it difficult to compete.

Process Power

Helmer defines Process Power as, “Embedded company organization and activity sets which enable lower costs and/or superior product, and which can be matched only by an extended commitment.”

This is the most elusive and hardest to nail down of the 7 Powers. It’s built up over time, in both intentional and unintentional ways. It’s in the culture and the explicit processes themselves. One of the key tests for whether or not a company has Process Power is whether an employee could jump ship to a sufficiently well-funded competitor and replicate your process to beat you at your own game. If the answer is no, you have Process Power. Think Toyota.

While “good processes” are too often elevated to “Process Power,” I think that Formic has the beginnings of real Process Power. In some ways, they have to, given where they operate in the stack.

As an as-a-service company, Formic’s job is to stitch a bunch of different complex things together to deliver one reliable, easy product to customers: robot labor by the hour. That means writing software to scope and design robots and creating simulations of the robots in customers’ environments and understanding which robots are right for which jobs (and which customizations they’ll likely need) and managing a complex supply chain of robots and components and knowing when to call in integrators (and which integrators for which jobs, where) and incorporating the latest AI to make the robots smarter (and knowing when it’s actually really ready) and deploying robots on-site and managing them remotely and predicting when they’ll need maintenance and knowing how to sell all of the above to buyers at the low and high ends of the market and getting it all financed appropriately and redeploying robots with as little customization and cost as possible when contracts expire.

Not only is that a long list of ands, orchestrating the timing among all of them is a complex dance. And even though the product is robots, the process has humans all over it. Part of Formic’s Process Power is the relationships and experience its team has built up over combined decades in the space. When the automated part of automating automation breaks down, Formic’s people know when to pick up the phone and who should be on the other end in order to unstick it.

In a sense, building Formic is building the process to automate the process of automating. It internalizes all of the complexity in the robotic automation market, and delivers a simple product to customers, by the hour. That might be another way to test Process Power: how much complexity can a company internalize and still make it look easy?

For a two-year-old company, Formic already does a lot of complex things well, across bits and atoms. From here on out, building Process Power will be about getting in reps, and about continuing to weave together culture, software, people, and institutional knowledge in ways that would-be copycats can’t copy.

Brand

Brand comes with a lot of connotations, but the textbook Helmer definition is “The durable attribution of higher value to an objectively identical offering that arises from historic information about the seller.”

When I started thinking through Formic’s powers, brand wasn’t the first that came to mind. Normally, we associate brand with consumer companies like Tiffany or Coca-Cola. I’m willing to pay more for a piece of jewelry from Tiffany with the same specs as a piece of jewelry from Kay because that Tiffany Blue box communicates something special to the recipient.

But upon further reflection, I actually think that brand will be one of Formic’s enduring moats.

To understand why, it’s important to remember why customers sign with Formic, or introduce robotic automation at all. It’s not about cutting costs. It’s about improving reliability and increasing output.

Done right, robotic automation drops enough profit to the bottom line that ensuring that the factory keeps humming is more important than an extra dollar or two per hour in robotic labor costs.

By being first to market with an easy and reliable product, Formic has the opportunity to build a strong brand among manufacturers. Right now, I would assume that many of Formic’s customers view deploying robots in their factories as a risk – it’s new – but a risk worth taking, because the options are “deploy” or “don’t deploy.” They’re going to go with whoever can offer them convenient and affordable robots that fill their urgent labor gaps. Today, that’s Formic.

Over time, as robotic automation becomes more widespread, the risk perception will shift from “whether to deploy” to “who to work with.” While price will always be a factor, I don’t think it’s the main competitive vector here.

If Formic continues to deliver for their customers, I expect there to be a “No one ever got fired for buying Formic” effect. Why work with an unproven startup that’s a dollar or two cheaper (ignoring Formic’s Scale Economies for a second) when everyone you know tells you that Formic’s working well for them?

Even in the early days, that’s starting to happen. Thomson Plastics’ CEO said that they chose Formic because he heard about its offering from “a friend of a friend” in the industry.

Brands are not made in two years. Formic will need to execute at a high level for its customers even as it scales from 50 deployments to 5,000 in order to earn the Brand power. But if they do, Brand could be the company’s most enduring advantage and prevent a race to the bottom.

All that said, while I love nerding out on strategy and moats more than the next guy, competition is a good thing in this case. Remember, the goal here is abundance, not scarcity. We need to deploy a ton of robots, and if we ever get to the point at which competition meaningfully drives down hourly rates, the world will be a meaningfully more abundant place.

Automating Abundance

“Why couldn’t we have a Ferrari for every person?”

That’s the question Saman posed as we were wrapping up our last call. And he gave his answer.

“We don’t live in a world of abundance. Most people don’t have enough of the things they want and need. We’re constrained by manufacturing capacity, which is mostly constrained by labor.”

Formic is trying to usher in the world in which everyone has Ferraris, and much more besides. A world of abundance.

In his piece laying out the Abundance Agenda, The Atlantic’s Derek Thompson wrote: “We should aim for abundance of comfort, abundance of power, and abundance of time.”

Robots won’t solve everything. The Abundance Agenda includes calls for more clean energy, more immigration, more housing, more doctors. To create abundance in these categories will require changes in legislation and the will of the people.

But robots can facilitate abundance by accelerating progress in an area the whole country seems to agree on: manufacturing. The government is pushing to bring manufacturing back home. Red and Blue states alike want more good, middle class jobs. Americans are happy to buy Made in America products, as long as those products are cost competitive. No one wants to wait months for a thing they need because of shipping delays or labor shortages. (I’m writing from the American perspective here, but the benefits hold in other countries, too, and de-globalization is happening everywhere.)

Companies like Formic and Hadrian are making manufacturing cool again. Manufacturing jobs can mean working at the cutting edge, making things that people need and making a good living doing so. Reshoring will only work if we can attract great people to build great things.

I came into this piece fully believing that we need more robots in order to make more things faster and cheaper. What I didn’t appreciate was the virtuous cycle robot deployment kicks off.

There are not enough people to fill all the manufacturing roles needed today, let alone in a more abundant, Made-in-the-USA future. Robots can fill the gap, and do more than that: they let factories run more shifts, increase profits, hire more workers for better jobs, expand, and reinvest in manufacturing quality products.

Take it from Formic customer Polar, which has been manufacturing in the US since back when it made parts for the Ford Model T:

It’s not about cutting labor costs, it’s about keeping up with demand.

There’s always this fear that the new technology will take our jobs. Tractors. AI. Robots. Whatever.

Instead, our quality of life continues to improve and humans find new, more uniquely human and fulfilling work.

If Formic succeeds, us humans will live in a world with more comfort, and as importantly, a world with more time.

We shouldn’t settle for screwing bottles on caps 8 hours a day, 5 days a week, for years on end in order to afford the things we need to buy, just like we didn’t settle for farming the land every day for entire lifetimes to produce the food we needed to eat.

By accelerating the adoption of robots, Formic is accelerating abundance.

OK, you made it this far, you must be interested in robots. If you want to get a job working with them, Formic is hiring a lot of humans. Check out open roles here.

Thanks to Saman for working with me on the piece, Garry for the intro, and Dan for editing!

That’s all for today. See you back here Friday for your Weekly Dose of Optimism. Have a great week.

Thanks for reading,

Packy

Interesting and helpful

I guess I’m interested in robots—great piece!