Hadrian: Ex Machina Ad Lunam

Meet the Anti-Decline Company Building to Keep the Solar System Free

Welcome to the 890 newly Not Boring people who have joined us since last Monday! Join 110,611 smart, curious folks by subscribing here:

🎧 To get this essay straight in your ears: listen on Spotify or Apple Podcasts

Hi friends 👋,

Happy Monday!

If you haven’t read a Not Boring piece in a little while, read this one.

Hadrian is different than the companies we normally talk about in Not Boring. While it relies heavily on software, its main focus is in the world of atoms. It uses big machines to make precision parts for rockets and satellites. It blends automation and high-skilled labor.

It’s an incredible example of something we’re going to see a lot more of in the coming years (partially because Hadrian exists): startups tackling very hard, government-level problems in the physical world (and space). I’m very eager to see what happens as the worlds of bits and atoms continue to interact and co-evolve.

If Hadrian succeeds in its boldest missions, Americans will build hard things with speed once again, we’ll grow a new skilled labor force by making manufacturing cool, and freedom will reign among the stars. High stakes.

Note that this is a Sponsored Deep Dive (read about my selection process and conflicts here) and Not Boring Capital is a small investor in Hadrian, but neither of those facts impacted the way I’m writing this. I’ve been this excited about Hadrian since my first call with Chris after Moshe at Shrug introduced us in February (thanks Moshe!), and if anything, I’ve held back my enthusiasm.

Let’s get to it.

Hadrian: Ex Machina Ad Lunam

Every startup has a lofty mission. Hadrian is the first I’ve encountered whose mission includes reversing American decline and ensuring the solar system remains free.

Chris Power, Hadrian’s founder and CEO, is clear about the stakes: if the US loses military and space superiority this decade, totalitarian actors won’t just take control of the reserve currency and power on the home planet, they’ll settle the solar system.

We’re in a second Space Race, one with astronomical stakes, and we’re at risk of losing because we can’t build like we used to. That’s what Hadrian wants to fix. Chris calls it the “anti-decline company.” He wants to remind people that we can still build hard things in the real world fast, like we did in the 1960s.

Part of the reason Americans can’t build like we could in the ‘60s is that we’re still relying on the same advanced manufacturing supply chain we were back then, two generations (and a lot of excitement and optimism) removed.

So to reverse decline, Hadrian plans to transform the legacy supply chain that powers space and defense manufacturing today into one that is faster, cheaper, more reliable, and more transparent.

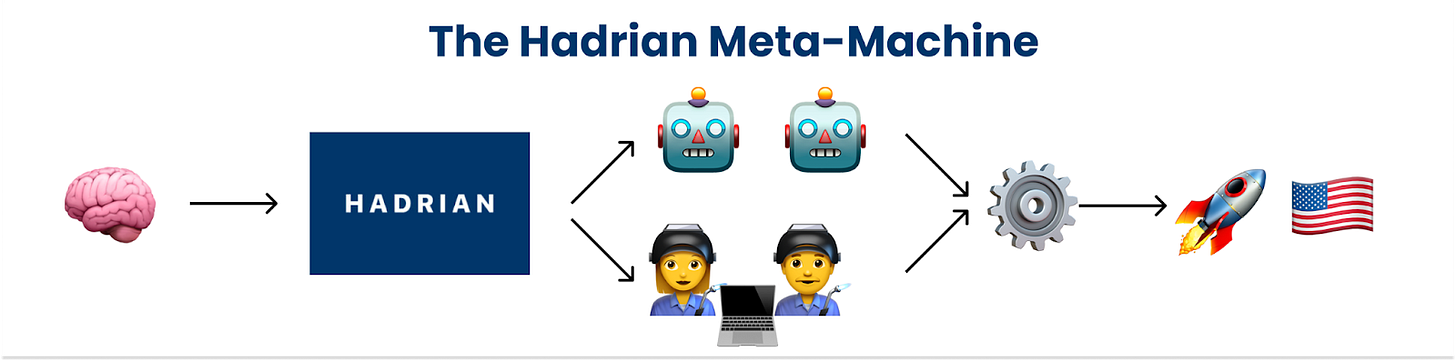

To do it, Chris has assembled the Avengers – world-class software engineers, machinists, CAM programmers, operations leaders, and data scientists – to transform the faltering legacy space and defense industrial base in the United States into a hyper efficient techno-industrial base. He warned them that it was going to be hard and painful, and they all signed up.

The team is building precision machine factories that automate the repetitive and mindless things that can be automated and create high paying, meaningful work around the things that humans do best. At the meta level, it’s building a machine that turns tribal knowledge into software, processes, and jobs.

Importantly, unlike self-driving trucks, which will automate tons of people out of jobs, machine shops literally cannot hire enough people to scale. To meet demand, there is no alternative but to simultaneously automate and train a new generation of skilled workers.

If Hadrian is successful, any company that relies on precision parts – starting with space and moving into defense, medical devices, semiconductors, and energy – will be able to build 10x faster and for half the cost that they’re able to today. That means faster iteration and cheaper costs for advanced rockets, satellites, jets, and hypersonics.

If that happens, US Defense will gain the manufacturing overmatch they need to maintain peace through strength on earth and in space. The US will win Space Race II. The solar system will be free. It’s a big vision.

But first things first, Hadrian needs to ship its tightly-focused set of first parts – high-margin, high-precision aluminum components for space companies – on-time and on-budget. It needs to continue to hire world-class talent from the worlds of bits and atoms and get them to work together to turn tribal manufacturing knowledge into scalable software and processes. IT NEEDS TO BUILD.

To help fulfill its mission, last week, Hadrian announced that it raised $90 million in two rounds: a Series A led by Brandon Reeves at Lux Capital and a Series A-Prime led by Katherine Boyle at a16z. Founders Fund and Lux led the Seed in March 2021.

Hadrian is Boyle’s first investment out of the firm’s new American Dynamism practice, and it’s an appropriate first investment. It is building critical infrastructure on top of which ambitious American hard tech companies will be able to innovate with atoms the way that software companies are able to innovate with bits. Hadrian will serve as the foundation of American Dynamism.

Hadrian is not the first company to try to build automated factories – in fact, it’s not the first company that Founders Fund and Lux have backed to go after the opportunity. The first one failed. Hadrian could fail too; what it’s trying to do is very hard. But the fact that both firms are back at the table with Hadrian is a testament to the size and importance of the opportunity, the timing, and to the approach that Chris and the Hadrian team are taking to tackle it.

Because for everything we’ll discuss about the strategic importance of settling space and enabling military superiority, make no mistake: Hadrian has the potential to build a massive business. It’s building a Keith Rabois-style “fat startup” in a fast-growing $30 billion industry with a highly-fragmented and outdated supplier base, pursuing software-like margins, and digging moats that will make it incredibly difficult to unseat. Hadrian has the potential to be a $10 billion+ business, and one that endures for decades.

It’s a prime example of a trend towards atoms-based businesses with enormous missions in categories like climate, healthcare, space, and defense – businesses that can do well by doing good, to quote the Protestants. A host of factors are intersecting at just the right time to make previously-impossible models possible and profitable, many of which we’ll discuss here and some of which we’ll save for a future piece.

But while the mission and the opportunity grab headlines, Hadrian’s real magic is in the details:

How do you automate the 80% of things that should be automated while creating great American manufacturing jobs to do the 20% that only humans can do?

How do you recruit the exact right people – often from cushy jobs at SpaceX or Stripe or Target or even out of post-Oculus retirement – to solve really hard problems?

How do you take the tribal knowledge in experts’ brains and turn it into processes and software that even a brand new hire can use to get really good, really fast?

How do you finance a capital intensive business in such a way that it scales like a capital-light one?

Rallying people around a huge, inspiring vision and focusing on the exact right details today to get there in time is a near-impossible balancing act. Luckily for Hadrian, there are very few people in the world as good at playing on different levels at the same time as Chris is.

The best leaders can take the “30,000 foot view” and zoom into the one-inch details. Both metaphorically and literally, Chris is able to take the 1,193,280,000 foot view1 and zoom into the micron-level details2.

Today, we’ll cover many of them. I’ve not been this giddy researching a company in a long time, and I’ve done my best to translate what I’ve learned, how Hadrian can win, and why I think it’s important:

We Choose to Go to the Moon

Powering Through the Idea Maze

How Precision Machining Works Today

A Plethora of Lessons

What Hadrian Does Differently

How Hadrian Works

7 Powers

Ex Machina Ad Lunam

Everyone I spoke to on the Hadrian team acknowledged that there’s a ton of execution risk in front of them. It’s never been done before. But that’s why they’re there. They choose to work at Hadrian not because it is easy, but because it is hard.

We Choose to Go to the Moon

On September 12, 1962, one year and two months before his death, President John F. Kennedy gave one of my favorite Presidential speeches in US History.

In it, JFK set a goal for the United States to send American astronauts to the moon by the end of the decade, essentially from a standing start. The Russians were far ahead of us. He acknowledged that it would be hard, but that that difficulty is precisely why we needed to do it:

We choose to go to the Moon...We choose to go to the Moon in this decade and do the other things, not because they are easy, but because they are hard; because that goal will serve to organize and measure the best of our energies and skills, because that challenge is one that we are willing to accept, one we are unwilling to postpone, and one we intend to win.

Aside from the stirring rhetoric and the grandness of vision, what makes this speech so special is – and I don’t want to spoil the ending, but… – we did it.

On July 20, 1969, less than seven years after the speech, Apollo 11 astronauts Neil Armstrong and Buzz Aldrin became the first humans to ever set foot on the moon. We beat the Russians. USA! USA! USA!

Over the next three years, NASA’s Apollo program completed five more manned moon landings – Apollos 12, 14, 15, 16, and 17 - concluding with Apollo 17 astronauts’ Eugene Cernan and Ronald Evans’ 75 hour stay on the lunar surface in December 1972.

And then… nothing. We haven’t been back since. This year marks the 50th anniversary of the last time an American set foot on the moon.

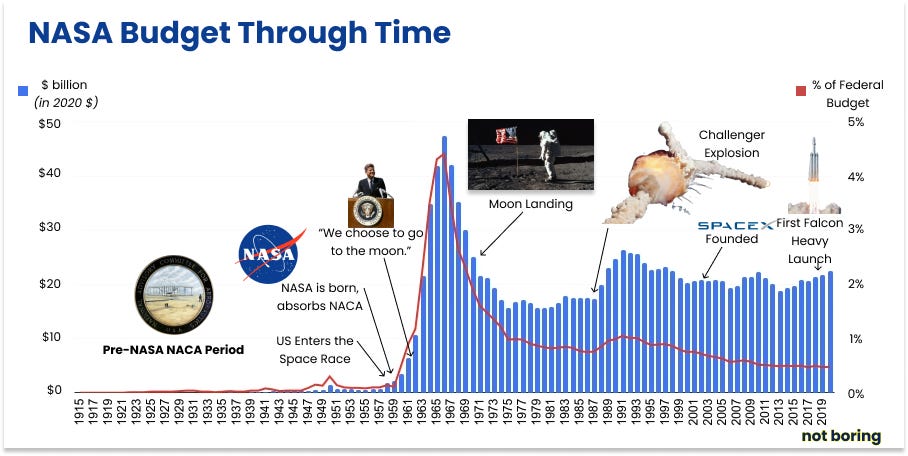

In the intervening half-century since the Apollo program, NASA’s budget fell off and has slowly declined as a percentage of the Federal budget (other than a post-Challenger explosion uptick). We won the Space Race. Mission accomplished. Our eyes returned to the ground.

Look up. The Race is back on. We’re in the early days of Space Race II.

If you haven’t been paying attention to what’s going on in the space, it’s time to start paying attention. Things are about to get sci-fi. In the next decade, there’s a very good chance that humans will establish the first Lunar base. The first humans might set foot on Mars. Wars might be won, lost, or hopefully, deterred, based on nations’ capabilities in space.

This sounds like sci-fi, but it’s very real. As the simplest example, satellites are crucial war infrastructure today; knock them out, and your enemy is blind. More extreme examples include “Rods from God,” simple tungsten rods, or even space rock, sent from space at 10x the speed of sound to hit precise targets with the force of a nuclear bomb. Space is a key battleground.

Commercial activity in space will inevitably pick up, too. It already is. SpaceX has inspired a nation with everything from its manned lockdown launch to its mission to make humans a multiplanetary species, but its most immediate impact has been dramatically lowering the cost to launch things into space by making rockets reusable and increasing their payloads.

During the first Space Race, it cost $177,900 inflation-adjusted to send a kilogram to Low Earth orbit (LEO) on NASA’s Delta E. SpaceX’s Falcon Heavy has dropped the cost two orders of magnitude, to $1,500/kg. Its forthcoming Starship – the one that might take humans to Mars – is going to slash the cost once again, to around $50/kg!

Elon is doing the Elon thing, lighting the match that ignites an industry, and it’s working. Today, companies can book space on a rocket for their satellites more easily than they can buy Enterprise SaaS.

SpaceX has a direct impact on space by making it cheaper and easier to fly things out there, but Chris pointed out that the bigger impact might be that it has “trained a bunch of 25-year-old engineers who are now 30-year-old engineers going out to start their own companies based on what they learned at SpaceX.”

Lower costs and more talent has led to an absolute explosion in the number of, and funding for, space companies: Varda, Hermeus, Astra, Astranis, ABL Space Systems, Ursa Major, Planet Labs, Epic Aerospace, LeoLabs… the list goes on and on. And then there are the companies that intend to compete with SpaceX, like Relativity and Blue Origin. There’s an excellent newsletter called Payload that you should check out if you want to keep up with space.

Plus, lower launch costs don’t just mean more businesses, they mean that these businesses are able to build more experimentally and iteratively, like terrestrial startups can. That should lead to all sorts of unimaginable innovations.

Think about what happens when launch costs drop. If it costs $25 million to launch your satellite into space, you better make sure that everything is perfect and that the satellite is going to last for a long time. You prioritize perfection over speed. But if it only costs $1.1 million to get your satellite up, you can test and iterate and experiment much more than you could before. When you can just reschedule and hop on the next launch if you slip on timelines, you can set more aggressive timelines. You can start to innovate much more rapidly… as long as the supply chain can support it.

All of these changes, big and small, have taken place in the last five years that add up to mean a rapid liftoff in demand for spacefaring things from the private sector. And that’s before getting to the growing demand from the government for defense and exploration.

“This is the perfect window to build this company,” Founders Fund’s Delian Asparouhov told me. “Supply needs were flat for sixty years and then they grew exponentially overnight, which completely overburdened the system.”

And oh yeah, we’re going back to the moon. NASA is teaming up with SpaceX (and potentially one more partner) to send humans back to the moon by 2025.

This time, the stakes are higher. This time, we’re staying. There’s a very real chance that whoever wins Space Race II – the United States or CCP – will determine whether our spacefaring descendents live in societies that lean autocratic or democratic.

It’s troubling, then, that the supply chain we’re using to go back is the same one we used to get to the moon in 1969!

For precision parts, the world’s highest-tech companies – from Lockheed Martin to all rocket companies, including the most innovative and vertically-integrated, to Varda and everything in between – rely on a network of roughly 3,000 shops that look something like this:

“I’ll leave you with this,” Chris told me the first time we spoke in February. “Imagine walking into a garage in LA that looks like it’s from Fast & Furious, five guys with three CNC machines. You see a turbine blade underneath a piece of cardboard and ask what it’s for, and it’s a rocket engine part. And that’s how the whole thing works.”

The current state of play presents all sorts of issues. First of all, the people who own these shops are in their early 60s, the second generation of families who got their start in machining during WWII. (Dom’s quote in Fast & Furious applies to hiring in these precision machine shops: “I don’t have friends, I have family.”)

The average machinist is in their mid-50s. In many cases, the son or daughter won’t take over the business for a number of reasons – they move away, the business is struggling, they want to do something else – so the shop will shut down, and the supply chain will deteriorate further. Which is a huge problem, because it’s buckling under the growing load already.

Hadrian is modernizing this supply chain by building a network of vertically-integrated advanced manufacturing factories. It’s doing everything itself: building factories, buying machines, and pairing machinists and software engineers to automate manual manufacturing processes. It’s building a factory operating system, Flow, to make internal processes more efficient, prepare to hire and train thousands of workers, and better communicate with clients.

It’s building from scratch to meet modern demands.

Off of a new base, it can even work with machine shop owners who are retiring to acquire their shops and retrain their people, tapping into existing infrastructure and skilled people to grow even more quickly to meet demand.

And it couldn’t have come at a better time. As capacity declines and demand increases, the problem is only going to get worse. The gap between what we want to and need to produce and what we can produce will widen.

Even in pre-Space-Boom times, lead times for parts could range from four to sixteen weeks. Now, the supply chain is overburdened and fracturing. Every new VC-backed space (or defense) company adds another straw to the camel’s back. Lead times get longer. Innovation declines (imagine if you had to wait four months between iterations in software). And the United States gives up ground to the CCP.

In that first conversation with Chris, on February 15th, nine days before Russia invaded Ukraine, he gave a specific example of the risk the country faces if we’re not able to improve manufacturing:

Take hypersonics. We’re far behind, and we’re not set up to catch up. Hypersonics are an engine problem, but even if you took the best engineers – the ones from SpaceX’s Raptor Team – and said go solve hypersonics, they couldn’t do it quickly. The supply chain can only get them parts in 12-18 weeks. They can’t do the rapid iteration they’d need to.

When Chris mentioned hypersonics, I thought we were talking years before it became a real issue. Within two weeks, Russia became the first country in the world to use hypersonics in battle.

It’s one of many examples that things that seem almost too futuristic to grok can have real consequences, today and far into the future.

The United States needs to be able to manufacture advanced technology fast and affordably. We need to be able to innovate in the world of atoms nearly as fast as we can innovate in the world of bits. We need to be strong enough not just to win wars, but more importantly, to make sure that they never happen.

The prize for getting it right is enormous, both directly and indirectly.

Directly, there’s $30-40 billion in annual high-precision parts spend in the US alone, and that number is growing rapidly with the rise of private space companies and increasing US government space budgets. These are specialized parts with the potential for high margins. There’s no dominant player, just that network of 3,000 mom and pop shops. Delays are rampant. Costs are too high. Customers are unhappy. There is a wide open opportunity.

Indirectly, if Hadrian is successful, the US will maintain its aerospace and military dominance and stop ceding ground to autocratic rivals. That might mean keeping the dollar as the global reserve currency, during a particularly important time in human history, when we begin to settle space. Plus, it will create good jobs and bring some swagger back.

It’s not going to be easy, and Chris knows that. It seems like part of the appeal.

“It would have been so much easier to start a SaaS company and print money. Hadrian is excruciatingly hard to execute, and it might fail,” he acknowledges, “But I believe it's the most important thing I could possibly be working on, regardless of the chance of failure or pain threshold required to do it."

It’s his life mission, one he’s been working towards for nearly a decade, starting halfway around the globe.

Powering Through the Idea Maze

If you were writing a book with a main character who bends metal to his will to ensure freedom spreads throughout the solar system, there’s a good chance you would name him Chris Power.

Beyond the name, though, Chris has the right brain and background to do exactly what he’s doing.

Last Thursday, I joined a Clubhouse with Chris, Marc Andreessen, and Katherine Boyle to talk about the new funding and the theme of American Dynamism. During the conversation, Chris explained how and why he chose Hadrian to work on for the next 35 years.

As an Australian, Chris saw the rise of the CCP around the globe. He knew that humans would begin to settle the solar system in the next decade, and he wanted to ensure that it would largely be settled under a free and peaceful universal order instead of a totalitarian one. And given that, he wanted to figure out how to contribute his unique skills:

Am I the person to go start Anduril? Absolutely not. Am I the person to go start SpaceX? Absolutely not. But do I have this weird mix of blue collar experience, financial engineering, and software development in complex environments that happens to kind of perfectly match this? Yes.

And then once you realize that, by building Hadrian, you speed up all these other important companies. And as those other companies speed up, you really help the country.

The company is the result of his multi-year trip through the Idea Maze.

In 2013, Chris Dixon wrote a blog post based on Balaji Srinivasan’s concept of the Idea Maze that good startup founders go through. Essentially, great founders can speed run scenarios for their startup by calling on history, analogies, theory, or direct experience:

The pop culture view of startups is that they’re all about coming up with a great product idea. After the eureka moment, the outcome is preordained. This neglects the years of toil that entrepreneurs endure, and also the fact that the vast majority of startups change over time, often dramatically.

Chris’ journey is as tangible an adventure through the Idea Maze as I’ve come across. When Chris first encountered the problem that would lead to Hadrian, he was in his native Australia, a couple years out of dropping out of Monash University to start working, running growth for a startup called Ento.

Ento was a SaaS platform that used data science to help blue-collar businesses with shift-based workforces better track, schedule, and balance their labor. Chris joined as the fourth hire to lead the heavily technical sales process. As he was working with clients, though, he realized that while businesses using algorithms and software to improve operations could fundamentally see 50-60% gains, they only ended up getting closer to 8-15% efficiency.

The problem wasn’t the software, he realized, but a number of fundamental incentive mismatches including change management issues and legacy systems that hindered implementation.

Software alone can make real-world business a little bit more efficient, but SaaS is often designed to win deals – which often means getting buy-in from the CFO – as opposed to making fundamental changes. Good software is necessary but not sufficient. Without knowing he’d entered the Idea Maze, Chris had already run into the first dead-end and crossed one solution set – pure software – off the list.

But the idea had moved forward; Chris knew what category he wanted to go after. He had caught the industrials bug, and specifically, he realized that there was an enormous opportunity in advanced manufacturing. A student of history, he realized the geopolitical importance of a strong industrial base. Plus, the industry perfectly fit the Keith Rabois formula for startup success:

But before he decided to vertically integrate a solution, Chris tried to do the other thing that you do when you find a large, fragmented industry with low NPS and an aging ownership base: a rollup fund.

If you couldn’t just give a plant software and expect it to follow the recommendations perfectly, you could buy a bunch of plants and make them use technology to increase efficiency.

So in September 2018, Chris flew from Australia to the United States, where the opportunity set was larger and the potential impact more impactful, and locked himself in a hotel room in Texas for two months. From that room, he made hundreds of cold calls to plant managers around the country, looking for the right industry within manufacturing to attack.

“If you want to be a billionaire, you need to be contrarian and right,” he explained, citing the old startup adage. “Another way of saying that is: where is the arbitrage? The arbitrage in this case was “‘find me another vaguely technical person willing to lock themselves in a room for months and cold call hundreds of plant managers.’”

It wasn’t fun. He felt nervous every time. But “when you feel weird, taking that psychological cost is the arbitrage moment.” Citing eight-time Mr. Olympia Ronnie Coleman, Chris shared his secret:

“Everybody wants to be a bodybuilder, but don’t nobody want to lift no heavy-ass weights.”

Through the conversations, Chris identified the industry he wanted to go after: Aerospace and Defense. In his conversations, he kept hearing the same things about aerospace over and over:

The new Space Race is on

The industry is highly fragmented

Customers are moving faster than suppliers

It’s actually possible to standardize the process

Importantly, the industry had the right ingredients to make an impact on Chris’ mission. Other industries, like food, paper, or plastics are probably ripe for efficiency, but Chris didn’t want to “make tomato soup manufacturing 1% more efficient.” So advanced space and defense manufacturing it was.

In September 2019, he launched a small private equity fund called ADSC to acquire strategic manufacturing plants in the aerospace and defense supply chain and make them more efficient with technology. The fund was humming along – he raised from institutions and ultra high net worth individuals, and had letters of intent out to a number of targets – when he realized that he’d hit another dead-end in the Idea Maze.

As Katherine Boyle explained in her blog post, Investing in Hadrian:

Financial engineering doesn’t solve the core problem of making aerospace and defense parts faster and cheaper. And most importantly, it won’t train a new generation of machinists to produce high-quality parts for a growing critical industry.

As Chris explained it, the roll-up strategy was actually likely to be financially very successful… but so what?

I had this real crisis of meaning twelve months ago, because I had to give up that kind of obvious path to success, but I ended up deciding that the only way to really fulfill the mission was to go back and rebuild the technology from scratch, to rebuild the culture from scratch.

When Chris was going through his crisis of meaning, he set himself a high bar: to build an Archimedes Lever of a company. One that, if it’s financially successful, would also have huge second and third order effects.

“No dog-walking apps,” is how he puts it. “90% of VC-funded companies could go away and there would be no impact on the world.” Whatever he built would have to be a company that, if successful, would have a real impact on his mission to reverse American decline, create meaningful jobs, and preserve peace through strength.

Why does an Australian care so much about American decline? To Chris, America is itself the Archimedes lever for freedom and self-determinism. Despite its issues, America is the strongest bastion of freedom and self-determinism in the world. It’s the Hadrian’s Wall standing between the solar system and autocracy. Making America as strong as it can be, his logic goes, is the highest leverage way to protect democratic values.

So in December 2020, six months into COVID, he gave the fund’s LPs their undeployed capital back (although many ended up angel investing in Hadrian) and decided to build the whole damn thing from the ground up.

Chris escaped the maze with a tough realization: Hadrian would need to vertically integrate and fix advanced manufacturing by itself.

How Precision Machining Works Today

To understand why what Hadrian is building is special, we need to take a quick detour to understand how a normal precision machine shop works (and what precision machining even means).

Precision machining means making metal parts to very tight tolerances, often within microns (1/1000th of a millimeter). If you can make a bench by marking something by hand with a ruler and get away with it as long as you’re accurate within a centimeter, the components that go into rockets and medical devices need to be much, much more accurate. Being off by a centimeter in aerospace would be unthinkably catastrophic.

While all of this sounds very high-tech, recall that the precision parts inside all of the nation’s most advanced space and defense technology come from shops that more or less look like this:

Inside those shops, there are expensive machines operated by machinists with decades of earned tribal knowledge locked in their heads.

So in a dramatically oversimplified example:

A rocket company might order a part from a shop and send over a CAD (computer-aided design) file with a model of the part along with additional specifications and tolerances that define how precisely the part needs to conform to specs.

Communication and scheduling, both between the shop and the rocket company and inside of the shop, are done via paper and email.

The shop then often manually figures out when it can have a CAM (computer-aided manufacturing) programmer turn the CAD file into instructions for the CNC (computer numerical control) machine, and when it can have machinists work the machines to make the exact parts specified.

At the (roughly) scheduled time, machinists set up the machines to make the part specified, doing complex trigonometry and FEA (finite element analysis) in their heads to adjust on the fly and prepare the machines to cut based on specific metals used, geometries involved, and more. This can be the most time-intensive part.

Then they hit go, make the part, adjust if needed, and then make the part again.

Once the part is made, the QA (quality assurance) team inspects the parts, often using a CMM (coordinate-measuring machine). There’s often tension between the machinists and QA, as you would expect of any relationship in which one person’s job is to tell the other they didn’t do a good enough job.

Approved components are shipped to the customer, who often has to do QA on their end as well in order to ensure that all parts were made within acceptable tolerances.

All of that means that manufacturing is more manual, slower, less reliable, and more expensive than it needs to be. According to Hadrian, due to lack of automation in three areas – scheduling & resource management, coordinating manufacturing processes, and CAM and CMM programming:

30-40% of parts are shipped late or have quality issues.

Lead times from bid to ship 6-18 weeks despite 3-6 week lead time promises. Delays are the rule, not the exception.

Parts cost 2-3x more compared to “should cost analysis.”

Low NPS industry – customers told Hadrian just 10% of suppliers are “good.”

Even worse, when I spoke to Hadrian’s team, many of whom worked at traditional precision machine shops before Hadrian, there are all sorts of structural, financial, and cultural problems that prevent things from improving.

Take the tribal knowledge. Many of these shops are run by the same families that started them, and employ their family members and friends. They’re unwelcoming to outsiders and disincentivized to train new people lest they lose their stronghold. So all of the knowledge that our advanced manufacturing base relies on lives inside of heads.

Or take the financial situation. These shops operate at 15-30% margins at best and down years might take them out. They could certainly use automation, but the risk-reward of hiring a software engineer to build automation for them doesn’t pencil out in the short-term, plus how are you going to hire good software engineers, and how will they fit in culturally? So you don’t invest and productivity slowly declines and the culture follows. Everyone blames each other.

To be clear, I’m not judging nor am I pretending to know any of this first-hand. I can barely make IKEA furniture. I’d be the most useless person in any of the nation’s 3,000 precision machine shops. But many of Hadrian’s employees have lived this for most of their careers and they were unanimous in the challenges of the traditional model.

They weren’t the only ones to realize that there needed to be a better way. Silicon Valley, as it’s wont to do, did too.

A Plethora of Lessons

So if the old, manual way doesn’t work, what if you could remove the machinists from the process? What if you could automate the whole thing entirely?

Launched in 2013, Plethora set out to build the factory of the future by creating “a manufacturing system that turns customer designs into custom parts using robotics and advanced software that we’ve developed in-house.”

Plethora raised $35 million from top funds, hired very talented people (some of whom now work at Hadrian), built automated factories in California and Georgia, and… failed.

Aside from the fact that what it was trying to do was really fucking hard, a few things went wrong for Plethora specifically, according to investors and former employees:

They tried to do everything in software, cutting the humans out of the loop, which meant years of wasted time trying to solve “hobby problems” that humans could easily do.

The offering was too broad – from prototypes to parts, different materials, different shapes, high-end and low-end, not precision-focused – Plethora wanted to do everything.

It was a little too early, both in terms of customer demand for high-precision parts and in terms of the financing market for a business like this.

Right opportunity, wrong execution, wrong timing. It’s a startup story as old as time.

“The thing that has always struck me about Hadrian,” Founders Fund’s Delian told me, “Is that the investors who led its Seed and Series A have invested in and failed to succeed in solving this problem in the past.”

Delian, also the co-founder, President, and Chairman of space manufacturing company Varda, led Hadrian’s Seed even after Founders Fund lost money on Plethora. Fellow Plethora investor, Lux Capital, led Hadrian’s Series A.

Lux Partner Brandon Reeves, who’s on the board at Hadrian, made a similar point. “We were investors in Plethora, which didn’t work for a number of reasons,” he explained. “For all of the reasons that didn’t work, this will.”

What Hadrian Does Differently

Part of the idea maze is first-hand experience, and part is learning from the mistakes of others. Hadrian seems to have done that. Both Brandon and Delian cite Chris’ focus and pragmatism as the biggest reasons that Hadrian will succeed where Plethora failed.

Focus

Instead of creating everything for everyone, Hadrian is starting with an incredibly narrow (and high-end) focus and making sure that it’s able to deliver parts on-time and on-budget before moving on.

It’s starting at the high-end of the market, a la the Tesla Roadster, with more price insensitive space companies. Even more narrowly, it’s starting with high-precision aluminum parts and only focusing on specific geometries (what advanced manufacturing people call shapes).

Where they’re playing in the market, the challenge is harder, the margins are higher, and the need for speed is more acute. Hadrian can dominate this piece of the market, build up a reputation, work closely with customers, and expand. Already, it has contracts with large space companies (it can’t say which ones).

Only once it’s able to reliably deliver on-time and on-budget, and produce real revenue and margins, will it expand. Once is does, it can expand in three ways:

More metals & alloys. Aluminum is very forgiving on machines. Each rung up the complexity ladder gets harder to automate – automating steel is about 30% harder than aluminum, but automating Inconel (commonly used in rocket engines) is 10x harder. Hadrian will expand from aluminum to the craziest alloys over time.

More industries. Space is the high end of the market, but Chris told me that Hadrian should be able to serve use cases in defense (up next), then medical devices, semiconductors, and energy, with the same machines and “tweaks of 25% to the software.”

Other types of manufacturing. Beyond machining, Hadrian’s methodology could solve 3D printing, wire EDM, tube bending, and 10-20 other manufacturing types.

By focusing so narrowly, Hadrian can get very good at execution and get dollars in the door in the coming months, as opposed to the multiple years it takes many deep tech startups, and avoid the “deep tech death spiral.”

Pragmatism

“The thing that most convinced me to invest was Chris’ ruthless pragmatism,” Delian said. “He’s able to identify and focus on the 20% of work that gets you 80% of the way there.”

If earth exists in the Goldilocks Zone, the range of orbits around the star that are habitable for human life, Hadrian exists in the Technology Goldilocks Zone in between the overly-manual way the supply chain currently works and the overly-automated approach that Plethora tried to take.

There’s little preciousness at Hadrian. As one Automation team member told me, “You get points for shipping parts, you don’t get points for being right.”

Hadrian also puts time on the same plane as money. That same person highlighted a time when Chris told him to stop negotiating with an overpriced software vendor in order to just get moving, saying “We can always revisit it in a year.” He pointed out that, “Chris is really good at figuring out where to push and where to just give in in order to move fast.”

That pragmatism and focus were enough to convince Founders Fund and Lux to give the space another shot.

After Chris responded to Delian’s tweets about space manufacturing in the beginning of COVID, the two began texting, and met up for a socially distanced walk in October 2020. They kept talking as Chris walked through the idea maze.

Every month or so, they’d go out to dinner to celebrate Chris’ birthday.

When Chris officially decided to wind down the rollup and pursue Hadrian, Plethora was in the process of dying. Chris was some random Australian dude trying to do something that, on the surface, looked similar.

“There were only like four people in the world who would fund something like this, and two of them had just lost money on Plethora,” Chris recalled.

But Chris’ pragmatism, along with the stamp of approval from Varda’s engineers, convinced Delian. He was in. He introduced Chris to other investors in the space, like Brandon at Lux, who called Hadrian’s deck, “One of the shittiest decks I’ve ever seen. I almost passed, but Delian’s reference made it worth a conversation.”

So Delian introduced Chris to the deck designer he used for Varda to talk to other investors, but also gave him a term sheet to lead the Seed. Lux, Floodgate, and Construct Capital joined the $9.5 million round. The rest is history.

Since raising its Seed less than 18 months ago, Hadrian launched its first factory in Hawthorne, California (which it did in 45 days), and is making progress on its second, a 100,000 square foot facility in Torrance, California.

That speed is a result of the pragmatism and focus that show up throughout the organization, in everything Hadrian’s employees do. In my research, I got the chance to talk to three of the teams at Hadrian – Machining, Flow, and Automation – to form a picture of how the whole thing fits together.

Here goes my non-mechanical brain’s best attempt to explain how it works.

How Hadrian Works

Hadrian’s meta-skill is turning tribal knowledge from art to process to software.

It automates what can be automated, and hires and trains humans to do what humans do best, and coordinates all of it with software.

Because the product is turning peoples’ knowledge into instructions – for other humans or machines – Hadrian’s secret sauce is and will remain its people. Specifically, it has hired some of the best people in the world at the intersection of software and mechanical engineering and built a culture in which each celebrates the other.

Hadrian pointedly doesn’t hire software-only people with no understanding or appreciation of mechanical engineering and getting their hands dirty. If you’re a very skilled software engineer who’s ever submitted a complaint about the lunch options at Google, Hadrian is probably not the place for you.

Instead, Chris is building a dream team from backgrounds that don’t normally work together in tech startups: “I’m just Nick Fury pulling together the Avengers.”

The team is a mixture of world-class software engineers, machinists, data scientists, CAM programmers, operations leaders, and more from SpaceX, Oculus, Facebook, Google, Plethora, Target, Tesla, Anduril, Rocket Lab, Stripe, and more.

Chris pulled at least two people on the team away from retirement to work at Hadrian because the challenge is so hard and its solution is so important that they couldn’t not work on it. Brandon told me that Hadrian has only lost one key hire it was pursuing.

Everyone at Hadrian seems to genuinely be aligned around the mission, and around the desire to translate things into software and processes as much as possible. It’s hard to describe without sounding cheesy, but Hadrian’s is an incredibly strong culture that’s very different from the normal startups I meet. There’s a sense of mutual respect regardless of role or level, and a selfless desire to just make the whole thing work. Maybe it’s a factory thing, the understanding that each link in the chain is crucial to a smooth operation.

Speaking of factories…

Hadrian’s factories might look like normal – if newer and cleaner – factories on the surface. There are a number of CNC machines operated by machinists throughout.

The first big difference is that all of it is orchestrated by Flow, Hadrian’s Factory Operating System used by everybody in the company.

All of the machinists on the factory floor have Flow loaded on tablets to walk them through each job, step-by-step.

Corporate employees have Flow loaded on their desktops to track the supply chain.

Flow is an internal enterprise resource planning (ERP) that tracks who’s on which jobs, which machines are being used, and more, and then assists in execution. As employees execute in Flow, that data feeds back into the system.

The beauty of Flow is that it works at so many levels simultaneously, with incredibly complex guts abstracted away into easy-to-follow checklists. In the background, it’s doing high-fidelity scheduling and factory simulation, built by world class operations data scientists, but the user-facing interface (Hadrian’s software engineers call the company’s machinists its users or customers) is a series of easy-to-follow steps on a checklist.

As workers complete steps, Flow learns, taking inputs from everywhere in the company – from receiving to machining to shipping – and adjusting scheduling and resource balancing accordingly. Because Hadrian is vertically-integrated, its users can seamlessly execute on the software’s recommendations, unlike Chris experienced at Ento.

Flow makes Hadrian’s process evermore efficient, and it also serves a second purpose: it helps onboard new machinists quickly. The company takes pride in being able to take line cooks, artists, and Chik-Fil-A employees and help them make high-precision components within a month. Chris explained that to revive America’s ability to build, he needs to make working in manufacturing and mechanical engineering cool again:

I want to be able to walk into a dive bar in Missouri and hear a 20-year-old kid mouthing off that he doesn’t want to work in finance, he wants to work in engineering. We need 100k skilled people over time and today, they don’t exist, so we need to train them.

At that scale, training, too, needs to be automated by turning experts’ knowledge into software. Hadrian employs some of the best machinists in the world, and its two teams of software engineers work to turn their knowledge into software.

The Automation team turns machinists’ knowledge into software that automates the parts of their job that can be automated by machines.

The Flow team turns the machinists’ knowledge on those things that humans do better into step-by-step instructions so that more humans are able to learn how to do those things.

For example, deciding how to fixture a part is very hard for software to do – like “spend five years of a couple PhDs’ time to maybe figure it out” hard – but relatively easy for a trained human to do. Hadrian’s top machinists can do it easily. So instead of being precious about automation, Hadrian’s engineers design the system such that humans can learn to do the things that humans do more easily and machines do everything else. The skilled machinists are freed up to work on ever-more-challenging problems.

The Automation team put it this way: “We want to let humans make important decisions, and use software to automate the repetitive stuff. Sometimes, it’s better to build an assistive tool than it is to automate.”

So the Automation team automates the things that can be automated and builds tools to help humans for things that don’t make sense to automate, and the Flow team turns all of the things that humans do into processes that feed back into the Hadrian hive brain.

The result is that, just 12 months in, the Hadrian team has built a factory that is already more efficient than competitors. I asked the machinists to describe how that manifests in their day-to-day.

They gave the example of setting up a machine to make a specific part, a time-consuming process that they do every day. Before, it might have taken an hour or more. Now, within twenty minutes they can have a pallet set up and ready to be making a part.

All of the prep work that we would have had to do in the moment is done ahead of time, so we don’t need to worry about “Oh, I need to go get this tool.” Flow told someone to set that tool up last night so we’d be ready this morning. Even file management: a click of a button tells which file to run on which machine. It’s the Magic Button – it removes the painful stuff that nobody wants to do.

This isn’t about replacing people; it’s about making them more efficient, making it possible for more people to learn how to do these good-paying, skilled jobs, and freeing up the experts to solve expert-level problems.

One machinist told me, “If I have to open a folder on my computer twice, we automate that. It’s like the Microsoft idea, ‘We like to hire lazy people to do hard jobs.’”

Another said, “It makes our normal jobs faster so that we can spend the rest of our time figuring out how to automate away little five minute tasks forever.”

As an example, one of the expert machinists spent three months working with the software engineers to set up a pre-setter so that, now, a brand new person can set up a tool as easily as he could. That’s not something you’d see in a normal machine shop, where tribal knowledge is guarded and there aren’t software engineers to work with anyway. But everyone at Hadrian is bought in on the idea that turning tribal knowledge into software sets both Hadrian and their own careers up for scale.

All of those little things add up: this process has led to 10x faster lead times from bid → ship and 40% efficiency gains, with a clear path to 70% efficiency gains over the next 1-2 years of R&D. While the biggest gains will come from cutting production times, Hadrian is removing time and cost from each step of the process:

That “Supplier Management” line item is important. Because all of the information lives within Flow, Hadrian is able to keep customers up-to-date throughout the process, automatically, without sending PDFs and spreadsheets back and forth. Customers can check to make sure that everything is on schedule, and adjust their production plans accordingly, instead of the guessing that they often have to do today.

All of this should translate into strong margins. From Chris’ foray into private equity, he learned that top legacy space and defense machine shops generate ~30-40% gross margins and modern tech-enabled manufacturers can earn 50% gross margins.

Experienced people, software-powered processes, and automation should mean that Hadrian can produce meaningfully stronger margins than even the best tech-enabled manufacturers.

Near-software margins on nearly $30-40 billion in annual spend up for grabs from a relatively concentrated customer base – and growing over 30% year-over-year – is sure to attract competitors.

Competition would be great for the mission: it would mean more brains and resources pouring into shoring up America’s Space & Defense supply chain and a better shot for freedom.

And competition will come, but it’s going to be tough for them to topple Hadrian. Maybe it’s not surprising that someone named Power is stacking up at least three of the 7 Powers.

7 Powers

The strategy book that I’ve cited most in Not Boring is Hamilton Helmer’s 7 Powers: The Foundations of Business Strategy. In the book, Helmer identifies and dissects the seven types of moats that companies can build. I like Flo Crivello’s succinct definition of moats: “Moats are those barriers that protect your business’ margins from the erosive forces of competition.”

I think that Hadrian is stacking (at least) three powers to build a unique moat: Cornered Resource → Process Power → Scale Economies.

Obviously, it’s early and these moats aren’t dug yet. But Hadrian has an early lead, and if it’s able to maintain it, here’s what I think will have happened.

At a meta-level, Hadrian is essentially a machine that turns tribal knowledge into software and processes. It uses those to build precision parts faster, more cheaply, and more reliably than anyone else.

That means that it needs to:

Hire and retain as many people with strong, unique tribal knowledge as possible,

Build a culture that encourages the whole team to focus on turning that knowledge into software and processes,

Then grow like hell at superior margins in order to widen the gap so far that no one can catch up.

If it does those three things – and it’s already starting to – Hadrian will dig some very deep moats. We’ll take each one in turn.

Cornered Resource

Building that machine starts with a Cornered Resource, which Helmer defines as, “Preferential access at attractive terms to a coveted asset that can independently enhance value.” A cornered resource might be patents, regulatory capture, or people. Helmer uses Pixar’s Brain Trust as an example.

Hadrian’s Cornered Resource is people, too. I don’t just mean “Hadrian’s people are great!” which is soft, but specifically that if Hadrian needs to turn tribal knowledge into software and processes, then the quality of the software will rely on the quality of the experts it hires.

According to Chris, Hadrian employs fifteen of the twenty best aerospace machinists in the country from places like Meta, Tesla, Amazon, Plethora, and Rocket Lab, plus a group of software engineers from places like Meta, Stripe, Oculus, and Google who also have experience with mechanical engineering. If you wanted to build a team better suited to attack the problem that Hadrian is attacking, you would have to raid Hadrian for all of its people.

That’s going to be really difficult to do because of the culture that Hadrian has already built. Across teams, the thing that came across loud and clear was just how much everyone there enjoyed working there. My notes immediately after my call with the Machining team got right to the point:

Culture is important in any company, but it’s particularly special here for three reasons:

Machining culture generally is closed. Multiple people highlighted that their old shops or companies were nepotistic and threatened by outsiders, so they don’t take the time to train new people. In this case, the machinists were excited about their ability to train newcomers and give them career opportunities.

Collection of World-Class People in a Wide Range of Roles. It seems that there are a bunch of people who are the best in the world at what they do, and instead of fighting with each other for dominance, they seem wildly cohesive and collaborative. Software engineers spend a ton of time with their laptops on the shop floor trying to learn from machinists, for example.

Egoless and Appreciative of Others’ Skills. I thought that there might be a tension between machinists and the software engineers trying to automate their jobs, but to a person, everyone was thrilled to get to share their knowledge and turn it into software so that they could focus on the next biggest thing.

I could go on about the culture, but suffice it to say, I think it would be very, very difficult for a competitor to lure talent away from Hadrian.

The group of people at Hadrian, and the way that they’ve learned to work together, creates the second power: Process Power.

Process Power

Helmer defines Process Power as, “Embedded company organization and activity sets which enable lower costs and/or superior product, and which can be matched only by an extended commitment.”

Process Power is the rarest and hardest to grasp. It comes from both the written and unwritten things, the experience that people build up working with each other, and the tacit knowledge that comes from doing novel things as a group.

In Hadrian’s case, the company both explicitly builds processes in Flow, which should ideally be able to be reproduced, but has also earned a bunch of tacit knowledge around how to do things that no one else has. For example, when the team is done launching two factories in eighteen months, it will be the only team that will know how to build out factories to the precise specs needed in such short time-frames. Every example like that is strengthened by the fact that Hadrian’s culture, processes, and technologies are designed to capture and encode Process Power.

“Our meta-skill is that we’re the only techno-industrial manufacturing team that has all of the right knowledge and knows how to turn it into software,” Chris explained.

So Hadrian has cornered the market on the talent needed to build this business, and then figured out how to get them to work together in new ways that would be very, very hard for outsiders to replicate. And they’re moving really, really fast to get to scale.

Scale Economies

Scale Economies, or Economies of Scale, should be a familiar power: “The quality of declining unit costs with increased business size.”

Thanks to its people and processes, Hadrian should be able to scale quickly. It already has a head start, and scale should help it cement its position.

As Hadrian gets bigger, there are obvious things that will drive down costs. Already, it’s vertically integrated on the raw materials side; it has aluminum, which is relatively cheap, handy. As it scales, it will pay less for those raw materials, which will become more important as it moves to more expensive metals like titanium and Inconel over time.

If and as it continues to pull away from the field, grow its customer base, and get contracted orders, it should also be able to drive down financing costs for both machines and raw materials. Every cost down it gets, direct and financial, makes it harder for someone else to catch up.

More importantly, because of the way it’s designing the system, Hadrian will also be able to scale across industries with the same factories. While it’s starting with Space, Chris told me that they should be able to move to Defense, Medical Devices, Semiconductors, and Energy with “tweaks to 25% of the software.” That means that it should have a sustainable advantage even over competitors who might try to come in and build more specialized “Hadrian for X” competitors.

I could also make an argument that Hadrian has the potential for high Switching Costs – if they know how to make a company’s very specific parts within tight tolerances, and if customers integrate their systems with Flow, there’s little reason to switch – and even Brand and Network Effects if I squint.

The point should be clear: if Hadrian continues to execute and gets over (very high) early hurdles – “I cannot stress how painful the next 12-18 months will be as we clear these hurdles,” Chris warned – it has characteristics that suggest that it will be a very hard business to unseat for a very long time.

As it grows, it gets stronger, pulling in more talent, turning their knowledge into process and software. As it nails one customer and component category – say aluminum parts for Space companies – it can focus its meta-machine-building attention on more uses – say titanium or Inconel parts for defense.

Brandon at Lux made a comparison that speaks to how unique Hadrian’s opportunity is: “The upside here is that this is the Taiwan Semiconductor of the aerospace and defense industry, an ‘n of 1’ company.” “TSMC” is the world’s 10th most valuable company at a $533 billion market cap. It’s achieved, and held onto, its position, according to Ben and David at Acquired, thanks to process power.

TSMC has built that process power up over 40 years and Hadrian is just getting started. To be clear, I’m not saying that Hadrian is anywhere close to TSMC yet. But that’s the comp, the upside upside case if everything goes right.

All to say, if Hadrian makes it past its first customer deliveries successfully, it may get very big and be around for a very long time.

What would that mean?

Ex Machina Ad Lunam

In January, a few months after joining a16z, Katherine wrote an excellent and prescient blog post: Building American Dynamism.

In it, she described technologists’ crucial role in reversing American decline:

I believe the only way to reverse the course of stagnation and kickstart nationwide renewal post-Covid is through technologists building companies that support the national interest. I call this American dynamism: it’s the recognition that seemingly insurmountable problems in our society demand solutions that aren’t simply incremental changes that perpetuate the status quo. These problems demand solutions from builders — and it’s never been more vital that startups tackle these serious American problems.

Three months later, the need for American dynamism is starkly apparent. Even those opposed to war – especially those opposed to war – were reminded of the importance of having a strong American military when Russia invaded Ukraine. For all of America’s flaws, it remains the world’s best hope against the creeping forces of autocracy.

Beyond the immediate threat, America, and the world, need to dream big once again. We need to believe that we can explore the solar system. We need to expand our economic playing field to space, where, among other things, we might one day find enough clean fuel to power humans’ expansive desires both on the home planet and beyond.

In building to explore space and strengthen defense, we will undoubtedly discover and create things that improve civilian life on earth, just as efforts for World War II yielded flu vaccines, penicillin, jet engines, radar, silicon semiconductors, and more technologies without which civilization would look very different today.

In order to both defend and explore, we need an industrial supply chain that can support the technologists and builders who want to push the boundaries of what humans can make in the physical world.

In its own blog post announcing the Series A, No longer tolerating the decline of American industry, Lux Capital’s Danny Crichton wrote:

Precision manufacturing is one of the most important ingredients to long term economic growth and human flourishing. Every additional degree of tolerance we can tighten — at cost or cheaper — can open up a wide range of new applications that have never been possible before.

That’s what Hadrian is trying to accomplish. Just as AWS dramatically reduced the cost of starting a software business, and API-first companies like Stripe, Plaid, and others meant entrepreneurs could focus on building differentiated products, Hadrian wants hard tech companies across industries to be able to spend less time, money, and headspace worrying about parts, and more solving the problems that they’re uniquely situated to solve.

I don’t think any of us – me included – are prepared for what the world looks like when hard tech infrastructure makes innovating in atoms nearly as easy as innovating in bits is.

Hadrian is years from achieving that objective, even if everything goes right. Success is far from guaranteed. One team member told me, “Don’t get us wrong – this is still messy. But the foundation we’re building and the people around the problems give me an extreme amount of comfort that messes will be cleaned up.”

But it’s hard to imagine a more worthy pursuit than building the platform on top of which the world’s most ambitious people can build. Like we’ve seen in software or web3 or even space, when entrepreneurs get access to new primitives, it’s impossible to predict what wild and useful things they’ll build, but it’s easy to predict that they’ll build wild and useful things.

If Hadrian is successful, a new generation of entrepreneurs will once again build physical technology that maintains peace on earth and elevates our hopes to the stars. It’s hard to imagine a bigger vision than powering the settlers of the solar system.

But first, Hadrian has a factory to complete, and processes to improve, and jobs to create. If it gets to the moon, it will get there one pragmatic step at a time.

Ex machina ad lunam. From the machine to the moon.

Thanks to Dan for editing, to Moshe for introducing me to Chris, to Delian and Brandon for the insight, and especially to Chris and the whole Hadrian team for taking the time to talk to me and explain what they’re building and how.

Not Boring Talent Collective

Over 400 smart, curious people are looking for jobs at companies like Hadrian and in the broader web3 and startup ecosystem, and 40 growing companies have already signed up to hire them. Whether you’re looking to hire or looking for a new job, sign up here.

Thanks for reading, and see you next week,

Packy

This is the average distance from the earth to the moon.

Precision standards for many of the parts Hadrian will produce are measured down to the micron level (1/1000th of a millimeter).

Hi, I love your analyses, but here I don’t really understand why the perception that only if the US wins “Space Race ll” will there be peace? What do you mean that the solar system will be free? Free by who? And if the US wins this race, then won’t they own space and contradict the concept of “free”?

What a joke. Everyone thinks machining is easy. Does the Chick-fil-a person know when to change their inserts before it breaks? Does the homemade ERP Flow system tells you when the material warp? Oh wait, their best engineers and scientist have everything figured out how to predict and fix everything. And by the way, the mom and pop shops are the ones actually building America... it's called small businesses, not corporate. Corporation gets all the tax write off, free investors money but it's the mom and pop shops that work hard and are actually building the economy. Anybody can build buildings with free money, but you can't build quality with no experience and no knowledge. Always love when people that have never worked in a machine shop always say, just push the green button and magically parts are done. What a joke. I would prefer to use Xometry at least they send parts to qualified mom and pop shops.