Welcome to the 234 newly Not Boring people who have joined us since last Thursday! If you haven’t subscribed, join 205,099 smart, curious folks by subscribing here:

Today’s Not Boring is brought to you by… Create

If you feel as motivated as I do after reading about Varda, now might be the perfect time to go get in the best shape of your life and start doing big things. Create can help. Dan set out to reverse the creatine stigma, and in just a few months, thousands of people are using it and confirming what he knew from the research: it works.

Get 20% off your first order with the Not Boring link.

Hi friends 👋,

Happy Monday! Hope you had a refreshing weekend; now it’s time to talk about space factories.

Varda is one of the most ambitious companies I’ve ever come across. It’s a space company and a biotech company rolled into one, with a hypersonic testing service thrown in for good measure. Not Boring Capital is an investor in Varda, and I’ve been talking to Varda’s co-founders, Delian and Will, about writing a piece on the company for almost two years. We decided to wait until the perfect time: launch day.

This afternoon, Varda is going to launch a drug manufacturing factory into space aboard a SpaceX Falcon 9 rocket. The factory will orbit the earth for a little over a month, running tests on the spacecraft and its drug manufacturing capabilities, and then come hurling back down into the Utah desert in mid-July.

Because Varda does both space and bio, I teamed up with Elliot Hershberg to tell its story. In addition to being our biotech partner, Elliot writes The Century of Biology. Little did he know when he started writing that the Century of Biology would play out both on the earth and above it.

I’ve told you that things were going to get really weird, and that the most interesting things were going to happen at the intersections. Varda is what I’m talking about.

Let’s get to it.

Varda: The Space Drug Factory

I was on a call with Varda co-founder and CEO Will Bruey the other day when, answering a question about how his company has been able to recruit so many SpaceX engineers, he said something that really helped put Varda in context:

“For all of us who’ve been at SpaceX for the past decade working on how to get up to space cheaply, once we did that, the question became: what do we do up there? Manufacturing was the obvious next step to a lot of us.”

No matter what happens next, where we currently stand in human history is marvelous in the original sense of the word. Going up to space is cheap! Manufacturing things in space is an obvious next step! What a time to be alive.

This afternoon, just 874 days into its existence, Varda will launch the world’s first commercial space factory into orbit. It’s the company’s first test flight en route to manufacturing drugs in space for use on earth, and a major milestone in humanity’s journey to expand our capabilities beyond our home planet.

The video ends with a catchy line: “Getting to space is old news. Now, it’s what you do when you’re out there that counts.” Getting to space is old news! Wild. For most of our species’ existence, getting to space was unimaginable.

For the vast, vast, vast majority of human history, everything that our ancestors did and made remained on earth’s surface and within its atmosphere. A picture of earth and all of the man-made things in the sky would have looked like this:

We became a spacefaring people in 1944, when Wernher von Braun and the Nazis sent the first human-made object beyond the 100 km boundary that defines space, the V-2 rocket.

It would take another thirteen years for us to send something out to space and get it to stay there, in orbit around the earth. In 1957, the Soviet Union launched Sputnik, the first artificial satellite to orbit the earth.

The Soviets struck again four years later, sending the first human, cosmonaut Yuri Gagarin, into space, where he orbited for 108 minutes on April 12, 1961 aboard the Vostok 1. Gagarin joined a small but growing number of satellites in low earth orbit (LEO), those little green dots.

The Soviets’ space supremacy spurred their Cold War rivals into action. In 1962, President John F. Kennedy “chose to go to the moon in this decade,” and in under seven years, NASA fulfilled his promise when Neil Armstrong took “one small step for man, one giant leap for mankind.”

The Americans had won the Space Race, but the Soviets continued on. In 1971, they launched the first space station, the Salyut 1, into orbit, marking the first time that humans could live and work in space for extended periods. They joined a growing number of LEO satellites (the green dots) and newer satellites further out in geostationary orbit (GEO, the purple dots) in their journeys around the earth.

NASA’s funding plummeted after the Space Race wrapped up, but it didn’t completely stop innovating. In 1981, the US launched the Space Shuttle, the first partially reusable spacecraft. The rocket itself couldn’t be reused, but the Orbiter, the plane-looking thing strapped to it, carried astronauts back down to earth in relative comfort compared to splash-landing in capsules.

The Space Shuttle would come in handy when, in 1998, construction began on the International Space Station, a cooperative effort between the US, Russia, Japan, Europe, and Canada. Humans have continuously inhabited the ISS since its completion in 2000, where they’ve conducted scientific research in microgravity spanning biology, physics, astronomy, and meteorology.

While commercial enterprises launched communications satellites, space remained largely the domain of the governments who monopolized launch capabilities until 2003, when Elon Musk founded SpaceX with the goal of building reusable rockets in an effort to dramatically lower the cost of getting things and people into orbit and beyond. In 2015, SpaceX successfully landed its Falcon 9 rocket for the first time, effectively firing the starting gun on the commercialization of space.

Just seven years after the first successful landing, the number of objects launched into space annually has increased 10x, from 222 in 2015 to 2,163 in 2022. The ramp has been particularly steep since 2018, when SpaceX launched the Falcon Heavy, bringing launch costs down from 10x from the turn of the millennia, to $1,500/kg. On April 20 of this year, SpaceX launched its first orbital test flight of the tallest and most powerful rocket ever flown: Starship. While the rocket exploded, getting that behemoth off the ground was another giant leap towards a future in which launch costs on Starship reach less than $100/kg.

We’ve written about it before, but it takes a lot of repetition for it to sink it. We can’t quite grok it yet ourselves. The existence of SpaceX and the dramatically cheaper and more frequent launches it offers makes space businesses not only possible, but economically viable.

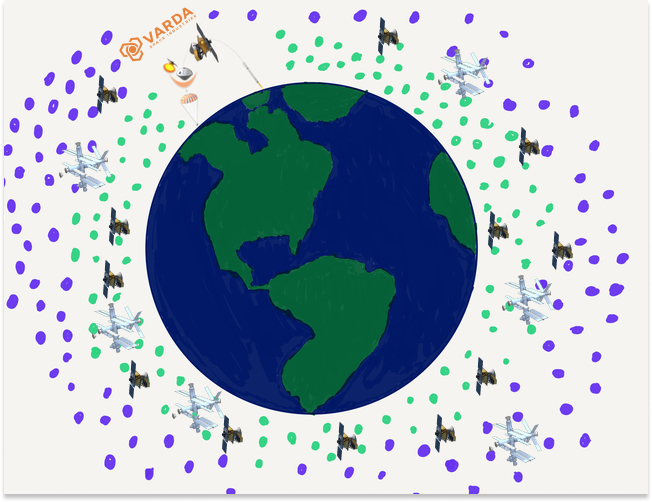

Satellites were the first step. Thousands of satellites, used primarily for earth observation and communication, dot the skies. SpaceX’s Starlink satellites make up a huge chunk of the objects in space, and their number is set to grow dramatically with Starship. In the coming years, cheap satellite internet will blanket the earth. Already, the map of 8,315 active satellites orbiting our planet looks like this:

But if we are to expand the economic bounds of humankind beyond our planet, the economy that evolves in space will need to mirror the one that’s developed on earth.

Today, we’re entering the next frontier on that journey. At 2:19pm PST this afternoon, Varda is launching the world’s first commercial space factory onboard a SpaceX rocket.

This first flight is mainly a test. Varda needs to prove, primarily, that it can send a factory to space, orbit it around the earth, and send a capsule with a payload safely back down to the planet’s surface.

If things go really well, Varda will also showcase its ability to manufacture drugs in space. It will crystallize ritonavir in microgravity in order to explore how gravity influences the resulting crystal structure. Ritonavir is a famous example of polymorphism in pharmaceuticals, where differences in the symmetry and structures of the crystals lead to drastic changes in solubility and bioavailability. By crystallizing pharmaceuticals in low-earth orbit, Varda seeks to explore how microgravity can be used to drive novel polymorphic outcomes.

It’s one small step on a mission to manufacture things in space for use on earth as we learn to manufacture things in space for use throughout the Solar System.

We’re lucky to be investors in Varda via Not Boring Capital and to have had an inside look at the company’s progress and future plans, and we can’t think of any better time to share them than right before the company’s potentially historic first launch. So today, we’ll cover:

The Varda Story

How to Build a Deeptech Company

Varda Goes to Washington

The Benefits of Dual Use

Manufacturing Drugs in Space

What to Expect from the First Mission

Expanding the Economic Bounds of Humankind

When you say the Varda concept out loud – space factories making drugs in orbit – it sounds crazy, or at least sci-fi, like one of those things that could maybe happen in the future but surely not now. But when you break down all of the things that go into making Varda work, from launch rideshares to satellite manufacturing to pharmaceutical research in microgravity, it all snaps into place: this is a futuristic sci-fi capability that’s both possible and practical today.

The Varda Story

If you’ve spent any time with Delian Asparouhov, the Founders Fund partner and Varda co-founder, it’s hard to imagine him locked inside with no outlet for his energy during COVID. Delian speaks so fast his words are measured in Machs. He dropped out of MIT with one course to go because they tried to make him sit through a CS class on a topic he already knew. I’m surprised the photographer was able to get him to stand still for this picture.

So when COVID lockdowns hit, and Delian was stuck at home with the venture market slowing and a bunch of free time, he started re-obsessing over an idea he’d been obsessing over for a long time: space. Specifically, Delian was interested in space manufacturing.

Space manufacturing, even manufacturing drugs in space, had made sense from a technical perspective for a while. Astronauts have been doing research on protein crystallization for decades, first on SkyLab in the 1970s, and on the International Space Station since it went into orbit around the turn of the millennium.

Shifting from research to manufacturing, and doing it economically and commercially, however, was still a moonshot. A company called Made in Space, founded in 2010, had seen some success building on-orbit manufacturing capabilities for the ISS, but it didn’t reach serious scale or make much economic sense and was acquired by Redwire in 2020. So space manufacturing was kicked into the “sci-fi things to do one day” pile.

But by the start of COVID, the stars were starting to align, on the macro and micro levels.

On the macro, the ZIRP environment was fertile ground for capital intensive space companies, something Delian noted on Twitter as he was noodling on the idea for Varda.

On the micro, space economics had shifted dramatically. Declining launch costs could make the unit economics of space manufacturing pencil out for the first time.

In 2019, author/astronautical engineer Robert Zubrin wrote a book called The Case for Space: How the Revolution in Spaceflight Opens Up a Future of Limitless Possibility. Zubrin would know; he was partially responsible for the Revolution in Spaceflight. In 1996, he’d written The Case for Mars, which inspired a young Elon Musk to start SpaceX. The 2019 installment took stock of the near-term implications of that company’s impact, and the long-term possibilities as we bumped into the limits of physics.

Zubrin goes through the math on a number of soon-economical space verticals, including rapid passenger travel, space tourism, space business parks, on-orbit research, and orbital industries. Specifically, he writes:

Could profitable mass-production operations actually be initiated on orbit?

The answer to this question depends upon a variety of factors, chief among them the cost of space launch, which today stands at roughly $5,000 per kilogram to low Earth orbit. At such rates, creating orbital industries is out of the question. But at the $200/kg rate that now appears to be achievable, matters change radically. In order for space-based manufacturing to be profitable, the value of the goods produced per unit weight must exceed this figure...

Taken together, these factors would tend to rule out almost all alloy or other materials production operations, but the production of advanced computer chips, unique pharmaceuticals, or lossless fiber-optic cables.

Reading the book helped convince Delian that the time was right to take space manufacturing out of the “sci-fi things to do one day” pile and make it a reality. He’d seen SpaceX’s impact firsthand.

We’ve shown this graph a bunch, because it’s the most important one underpinning the explosion of activity in space:

SpaceX’s impact extends beyond costs, though. Elon’s rocket company has also made getting to space more flexible and trained a new wave of space talent.

To make space manufacturing work, Delian would need to leverage both of those opportunities. Easily bookable (and moveable) ridesharing would mean more flexibility in product development and scheduling to meet customer needs. And the availability of SpaceX-trained talent – a rare group that possessed both rocket scientist smarts and Silicon Valley speed – would mean faster ramp times and a higher likelihood of success for the companies alluring enough to hire them.

That was the first thing Delian needed to prove to himself before starting the company: that he could get the right early people onboard. To be successful, the company needed to excel at three key things - manufacturing in space, getting the payload back to Earth, and selling to both commercial and government customers. He’d need leaders who were world-class in each of the three.

Will Bruey, Varda’s co-founder and CEO, is an expert at getting things back to earth. He spent over five years at SpaceX, where he led hardware engineering on the Dragon and was the primary mission control operator for the spacecraft during flight. There are very few people in the world who know reentry like Will does.

SpaceX is one of only two private companies to successfully re-enter from orbit, and when they re-enter, they do it in the Dragon capsule on which Will led hardware engineering. In March, four SpaceX astronauts splashed down in the Gulf of Mexico inside of a Dragon capsule. (Video of Dragon test landings.)

Will said that when Delian reached out, it didn’t take a lot of convincing to get him to join on as CEO. As he mentioned in the quote at the top of the piece, space manufacturing, while a wild futuristic idea to the rest of us, was something he and his fellow SpaceX engineers had been anticipating for a while. And he thought the approach that Delian laid out was the right one.

Delian and Will incorporated Varda Space Industries, Inc. and incubated it out of Founders Fund. In the tradition of Founders Fund-founded aerospace and defense companies, the name Varda was plucked from the pages of J.R.R. Tolkien’s The Lord of the Rings.

Palantir, the $31 billion public company that helps government clients visualize and analyze data to make better decisions, is named after the book’s seeing stones that allow their users to communicate and view events over large distances.

Anduril, the $8.4 billion startup that “transforms defense capabilities with advanced technology” for western defense clients takes its name from the sword of Aragon whose name means “Flame of the West.”

The company that would bring manufacturing to space, then, would be named after Varda, the Queen of Valar who made the stars.

In December 2020, the newly formed Varda raised a $9 million Seed round co-led by Founders Fund and Lux Capital.

Varda now had the money and the expertise to send things from the heavens back down to earth, but they still needed to figure out how to make things up there.

When he was considering joining Varda, Will called his Cornell classmate, Adrian Radocea, a materials science PhD who’d been working on materials for semiconductors, to ask a crucial question: “Does microgravity matter for materials?”

Adrian was dismissive: “Absolutely not,” he told Will. “At the atomic scale, the force of gravity is nothing compared to the electrostatic force.” (The electrostatic force between a proton and electron is 1036 more powerful than the gravitational force.)

But it was COVID, and Adrian was stuck at home, too. So he started reading scientific articles on the question and came across literature on the effect of microgravity on protein crystallization. Turns out, microgravity does matter at the mesoscopic scale, the length scale on which objects are larger than nanoscale (on the order of atoms and molecules) but still small enough that quantum mechanical or other non-trivial "microscopic" behavior becomes apparent. This is the scale at which protein crystallization occurs, which has important implications for pharmaceutical manufacturing.

He called Will back to tell him that there might actually be something there, and that he wanted to come help figure it out. Adrian joined Varda as the Head of Product.

Now the only questions left were what exactly to make and who would be willing to buy it.

So Delian and Will tapped Eric Lasker, a physicist by education who worked as a cook at Michelin Star restaurants before transitioning to the business side of startups. Eric worked in Enterprise Sales and Market Development at Stripe and then led US Federal Partnerships for Zipline, the autonomous drone delivery company.

They gave him his task: “Go build a business.”

They knew that they’d be able to launch factories into space, make things up there, and send them back down, and they had ideas about the types of things you could make up there and that a rare commercial reentry vehicle that didn’t have human cargo might be valuable to the DoD, but that was about it. There were no comps for a business like Varda.

January 19, 2021 was Day 1 at Varda. Will, Delian, Adrian, Eric, COO Jon Barr, and a handful of aerospace engineers got to work.

The engineers, many of whom Will had brought over from SpaceX, knew where to start. They’d need to figure out how to build their satellite factory and capsule.

Meanwhile, Eric and Adrian started figuring out which markets to attack first, and who would be willing to pay them for their out of this world capabilities, and quickly.

How to Build a Deeptech Company

Building deeptech companies is Hard. That’s why we like them so much at Not Boring.

It’s hard for a number of reasons. There’s technical and/or scientific risk. You need to hire people with very specific, in-demand skills. Hardware is hard. Buyers can be slow and stringent. R&D may eat up a lot of cash. The list goes on.

Delian’s now seen this from both sides of the table, as a partner at Founders Fund and the founder of Varda, so we asked him what it takes to build a successful deeptech company.

He said there are two main components: balancing the stool and generating revenue quickly.

The first is that “you need to know what milestones investors are going to be looking for at the Series B and operate to them. I don’t love the idea of operating companies on behalf of what investors want to see, but when you’re running a deeptech company, you have to do that.”

He describes the milestones as a three-legged stool that needs to be kept in balance at all times:

Build a top-tier technical team.

Achieve your technical milestones.

Generate the appropriate level of BD and sales interest in what you’re building.

Hire the technical talent you need to hit your technical milestones, hit them, raise capital, then freeze hiring while you gauge customer interest and continue to make technical progress with the team you have. When you find customer interest and approach further technical milestones that need new expertise, hire, raise, then freeze and do it again. If a normal startup is like a street musician, he told us, then a deeptech company needs to operate like an orchestra.

Varda has balanced the stool extraordinarily well.

1. Top-tier technical team. In just two and a half years, it’s hired a team of 70+ people, “at least 15 of whom would be very senior executives at other companies,” according to Delian, and many of whom have engineering experience at top space companies and drug manufacturing and BD experience at large pharmaceutical companies.

2. Technical milestones. On the launch side, Varda has remained remarkably on-schedule, and the schedule was aggressive from the beginning, slipping on the first launch date by just one quarter. One of the company’s values is that the trains run on time. Going from founding to launch in under 2.5 years is no small feat.

On the manufacturing side, the Varda team has been hard at work defining their plan of attack for pharmaceutical manufacturing, publishing early work on identifying new drug polymorphs.

3. BD and Sales Interest. Varda has generated significant BD interest on both sides of the business, from both the DoD and some of the world’s largest pharmaceutical companies. The company is executing over $60 million in programs with the DoD, and is on the precipice of finalizing a contract with a top 20 biopharma company for its second mission.

The stool has remained balanced. That’s half the battle.

The second component is that deeptech companies should begin generating revenue within three years.

Venture capitalists have investors, too: their Limited Partners (LPs). LPs typically expect to get their cash back and more within ten years. VCs typically invest each fund over two to three years, which means that once companies are funded, they have seven to eight years to return capital.

“If you’re not making revenue in year three or four, the likelihood you’ll be able to return capital to investors by year seven is low,” Delian explained. “It’s like a law of VC physics based on fund timeframes.”

Deeptech companies need to continuously raise capital to fund further milestones before they become profitable, so they need to continue to be an attractive investment for VCs. Therefore, deeptech companies can’t wait around in the pre-revenue R&D phase for too long, because they need to show investors that they’ll generate a return within the life of the fund.

I bring this up for two reasons:

It’s potentially useful to those of you building deeptech companies (and I hope there are a lot of you reading this)

To highlight the urgency with which Eric and Adrian needed to find someone willing to pay Varda for its unique capabilities.

So who was it going to be?

Varda Goes to Washington

Varda’s top priority is and always has been manufacturing things in space. The fact that its return capsule may also have value to certain customers is a valuable bonus.

But when Eric looked at the company’s technical timelines, with the mandate to start generating revenue as quickly as possible, he realized that Varda would have a reentry platform before it would be able to manufacture materials. So he’d try to monetize the reentry platform first, and got to work figuring out who would be willing to pay for it. The answer would emerge out of the engineering team’s work on how to make sure the capsule didn’t burn up as it re-entered the atmosphere.

While Eric was searching for the first platform customer, Will and the engineers – a growing group with backgrounds at SpaceX, Blue Origin, ABL, and Boeing – began building the spacecraft.

Varda’s flight missions comprises of four major pieces of technology:

Launch vehicle

Satellite bus

Manufacturing module

Reentry capsule

It’s a great time to be building a space company. As Will told us, “Each piece of what Varda does has been proven to work; what we’re building is only novel in the aggregate.”

As discussed, it’s now possible to hitch a ride on a SpaceX rocket to get up to ~500km Sun Synchronous Orbit (SSO). But there’s a growing supply chain beyond launch that gives space companies buy versus build options for a growing number of the things they need to do. As with any traditional business, space startups can buy the commoditized pieces of their product so they can get to market faster and focus their efforts on what differentiates them. Instead of building its own satellite buses, for example, Varda buys them from another space startup, Rocket Lab.

Varda buys space on the launch vehicle and its satellite buses so that it can focus on the reentry capsule and the manufacturing module within it.

The reentry capsule is fairly simple, or at least much simpler than the reentry capsule Will was used to working on at SpaceX. Those capsules needed to bring humans safely back down to earth, which meant that they needed to be overengineered at great expense to prevent any failures or even extreme roll. As a result, the SpaceX Dragon capsule can cost around $50 million. Varda’s capsules don’t carry human cargo. That means they don’t have to be engineered to the same high tolerances as the Dragon, and that they can reenter the atmosphere at steeper angles and higher speeds.

Higher speeds mean more heat, so the most advanced technology on the reentry capsule are the thermal protection shields (TPS) that keep the capsule, and the valuable cargo inside, from burning up. Here, too, Varda was able to partner. Decades earlier, NASA had developed TPS using an ablative material called C PICA, or Conformal Phenolic-Impregnated Carbon Ablator. Ablative is a big word that means that the material burns off under high heat conditions, carrying the heat away with it.

In an interesting catch-22, however, NASA couldn’t use the material on a live mission since it hadn’t been flight tested on a prior mission. By using it on a Varda flight, NASA could get it flight rated and begin using it itself. As Eric was talking to NASA Ames about the TPS, he and Varda’s Head of Hypersonics dug up a paper that had proposed a capsule very similar to Varda’s to test it, and then discovered that the Air Force had discussed a similar project and even gotten through the early stages of the process. He had his first targets for the platform.

An even more urgent need quickly followed when China shocked the world, and surprised US intelligence, by testing nuclear-capable hypersonic missiles in August 2021.

Hypersonics, as the name implies, fly at hypersonic speeds, or greater than Mach 5. The slowest, hypersonic cruise missiles, can reach speeds of Mach 5 to Mach 10.

The fastest, hypersonic boost glide vehicles, can fly as fast as Mach 25. Boost glides launch into space on a rocket before decoupling and orbiting the earth under their own momentum. What makes them particularly fearsome is that they don’t follow a fixed trajectory and can be maneuvered, making them harder to track and destroy.

America’s missile defense systems are designed to protect against more predictable ballistic missiles, but our ability to defend against hypersonics is far less developed, in part because we didn’t believe they posed an imminent threat. China’s revealed capabilities put the DoD on high alert.

General Mark A. Milley, the chairman of the Joint Chiefs of Staff, said in a TV interview, “I don’t know if it’s quite a Sputnik moment, but I think it’s very close to that,” adding, “It has all of our attention.”

America needed to beef up both its defensive and offensive hypersonic capabilities, and quickly. The challenge was: there aren’t many good ways to simulate hypersonic flows.

On earth, it’s possible to test components in blowdown tunnels – high speed wind tunnels – that can reach over Mach 15 for short periods of time. Those speeds come at the expense of the correct flow enthalpy, pressure, and chemistry. In other words, even if they can hit high speeds, tunnels can’t reproduce proper flight regimes to fully test hypersonic vehicles.

In space, a dedicated mission on a human-rated capsule like the SpaceX Dragon could cost $200 million ($50 million to make the capsule, $150 million for the flight) since the capsule needs to be overengineered enough to fully protect humans. Plus, Dragon is built primarily to protect the humans onboard. Because of its blunter shape, it slows down at higher altitudes and therefore doesn’t go through the boost glide flight regimes, experiences lower heating, and doesn’t experience the same g-forces.

Those two options mean either frequent cheaper tests in unrealistic conditions, or infrequent expensive tests in closer-to realistic conditions, neither of which is ideal for understanding the unique dynamics of hypersonic vehicles in true flight environments.

Varda, the team realized, might be able to fill that huge gap in the middle, allowing the hypersonic community to test in a true flight environment “early and often.” To get the products it makes in space into the hands of customers on earth, it needs to send its relatively inexpensive (non-human-rated) capsule hurling back down to earth at Mach 25+ anyway.

Eric had discovered the first customer, and one with an urgent enough need, and big enough budget, that they’d be willing and able to pay Varda meaningful revenue within that critical three year window. So he dug into the US Budget and the Defense Authorization Act – “I ctrl+F’d through a lot of horrible documents” – figured out potential buyers in the government, and approached them with a clear idea of what Varda would be able to offer.

Turns out, they were very interested. In March, Varda announced that it had been awarded a $60 million STRATFI program with the Air Force “to advance our nation’s hypersonic capabilities.”

The contract, which is essentially half-revenue and half-funding, covers two flights: one rideshare flight at and one dedicated flight, and additional work to create an enduring capability.

It’s an important milestone on the path to SBIR/Phase III contracting, at which point the DoD will be able to more easily purchase further flights from Varda. In the near future, Varda could be doing 4-6 missions per year on hypersonics alone, before accounting for demand from the government’s efforts to modernize its hypersonic vehicle programs. The goal is to have a rideshare on every flight, and Varda is currently lining up and signing a deep manifest beyond its first two contracted missions. STRATFI is a springboard into larger DoD budgets.

While space manufacturing is Varda’s top priority, securing government contracts so early in the company’s life actually gives the company more flexibility on the manufacturing side. The government is able to get better pricing because Varda has to send drugs back to earth, pharmaceutical companies are able to pay lower upfront costs because the government is covering part of the flight’s costs.

The Benefits of Dual Use

Nick Szabo’s 2006 blog post, How to succeed or fail on a frontier, is one of my all-time favorites. In it, he tells the story of the early Chinese and Portuguese naval fleets and explains why, despite China’s far vaster wealth and far larger fleets, Portugal succeeded in conquering the world’s sea trade routes while China shut down its program and turned in on itself.

The Chinese fleet set out primarily to show off the glory of China and secondarily to collect tributes, which weren’t nearly enough to fund itself. When the Emperor realized that the expeditions were expensive and pointless, he killed both the government-funded “treasure fleets” and the productive private merchant fleets that had successfully operated independently.

The Portuguese fleet, on the other hand, paid for its own expansion. As Szabo explains (emphasis mine):

Assisted by navigators and investors from other parts of Europe, the Portuguese embarked on a pay-as-you go path of conquest and trade. They focused on conquering strategic points that allowed them to control, tax, protect, and enable trade. They enforced the property rights of their allied merchants and otherwise enabled the commercial institutions by which that trade could flourish.

Szabo told the centuries old story to highlight a more modern one:

When it comes to the "final frontier" of space, it seems to be so far the West that has stepped into China's old shoes. What did Apollo return but glory and a handful of rocks? We proved that our socialists, if funded by taxing capitalists, could beat their socialists funded by socialists. Did such proof of bureaucratic glory really require 1% of our GDP over several years?

Like the Portuguese, Szabo argued that the West should engage in the “pay-as-you-go” flavor of space development. Instead of the $1.5 billion-per-launch Space Shuttle and plans for Moon and Mars bases, he advocated for launching more satellites into orbit for communications and surveillance, which serve both military and commercial purposes.

As the drawings in the introduction show, Sazbo got his wish. The year prior to the post, 2005, marked a nadir in the number of objects sent into space. That number has rocketed from 72 in 2005 to 2,163 in 2022, thanks in very large part to a private company, SpaceX, and the dual-use nature of its technology.

Dual-use technology is an important concept to understand. It refers to technology that can be used for both civilian and military purposes. Think nuclear fission, the internet, and GPS, or satellites that can be used for military reconnaissance and to deliver internet to off-the-grid customers.

The main benefit of dual use technologies is that they can command the government funding needed for the capital intensive early research and development (R&D) phase as well as the commercial market demand that incentivizes competition, cost improvements, and innovation. No private company could have funded the creation of GPS, and no government could have used it to create Uber.

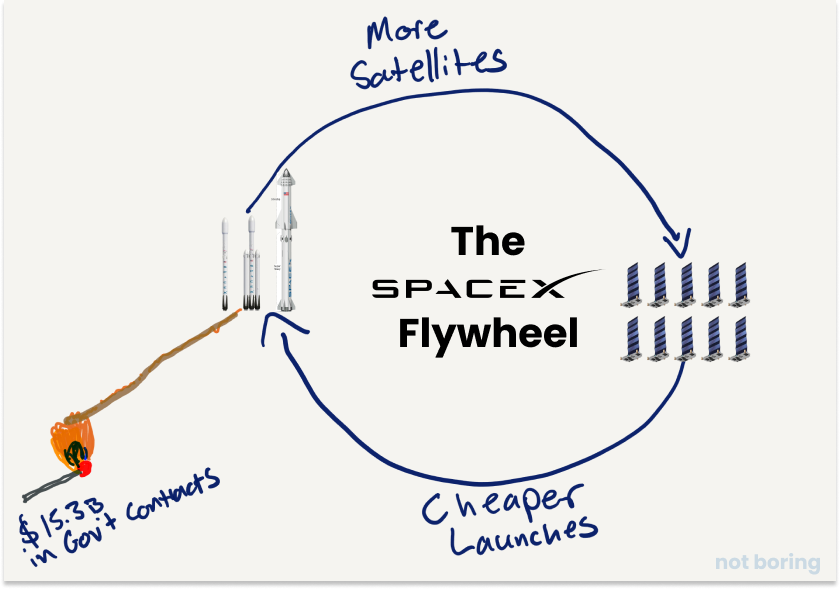

Similarly, SpaceX has benefited from $15.3 billion in government funding and contracts over the past two decades, which it has used to build a business that’s strong enough to both stand on its own and support a flourishing space economy.

Today, SpaceX has its own two uses which support each other: SpaceX and Starlink. SpaceX is able to build bigger and bigger rockets, and fill them with revenue-generating cargo, because Starlink is able to sell into the practically bottomless market for communications. Starlink is able to launch so many satellites because of the cheap launches provided by SpaceX’s bigger and bigger rockets. Together, they’re spinning a flywheel that makes it exceedingly difficult for any launch or satellite company to catch up.

As Casey Handmer concludes at the end of his two-parter, The SpaceX Starship is a very big deal and Starlink is a very big deal, Starlink and Starship wouldn’t exist without each other, and our near-future spacefaring capabilities would be nowhere as ambitious without both of them. “A ubiquitous, generic, and cheap Starlink is not possible without Starship,” he wrote, and “Starship, a launcher cheap enough to be interesting, is not possible without Starlink.”

On the way to fully industrialized cities in deep space, SpaceX’s cheaper and more frequent launches make other on-orbit capabilities economically viable for the first time.

Varda is pursuing a similar strategy: building dual-use technology to make its offering more attractive to each of its customer bases in order to build up a lead that will be hard to catch up with.

The company has two business lines:

Pharmaceutical Manufacturing (Primary). Varda works with pharmaceutical companies to design and manufacture drugs by leveraging the unique characteristics of microgravity.

Reentry-as-a-Service (Secondary). Varda’s reentry capsule is perfect for hypersonic testing because, without needing to carry humans, it can reach speeds of Mach 25+. The company recently landed a $60 million STRATFI program with the Air Force.

The dual-use nature of the business allows Varda to gain advantages on both sides.

Recall that if the DoD wants to test its hypersonic capabilities, it has two main options: use wind tunnels on earth (which doesn’t fully simulate conditions) or do expensive dedicated flight testing (which costs upwards of $100 - 200 million per test).

Because Varda is going up to space and reentering anyway in order to manufacture drugs, it’s able to sell “rideshares,” or “reentry-as-a-service,” that provide the DoD with a realistic testing environment for a fraction of the cost.

On the commercial side, the DoD contracts can cover a large portion of the cost of the flight, which means that it’s able to offer pharma companies a lower upfront price and capture more of the value it creates in the form of milestone payments and royalties. That makes working with Varda a lower-risk proposition, and the benefit is already showing up in the progress it's made with some of the world’s largest pharmaceutical companies.

Taken together, because it’s able to offer a valuable service to each side at a lower price than they would be able to without the other, Varda can fly more missions than it would be able to if it only worked with the DoD or pharma alone. More missions means that Varda will be able to bring down its costs significantly over time through integration and volume, which should drive even more demand. Varda is creating its own SpaceX-like flywheel.

The flywheel only spins because Varda is able to offer something valuable to pharmaceutical companies. After decades of researching the effects of microgravity on drugs on the ISS, pharma will now be able to actually manufacture drugs in space.

Manufacturing Drugs in Space

In The Case for Space, Zubrin estimated that even with $200/kg launch costs, a space manufacturing company would need to generate at least $80 million in revenue, or 40 tons of product, to cover its costs. This economic reality is why Zubrin made the argument to focus on “advanced computer chips, unique pharmaceuticals, or lossless fiber-optic cables.” They’re the highest value-per-weight products that benefit from microgravity.

It turns out that Zubrin was far too conservative, which we’ll address, but his larger point stands: space manufacturing companies should start with the highest $/kg product they can make and sell.

After deeper market research, it became clear to the Varda team that starting with drugs made the most sense.

The two products that have most reliably delivered venture-scale returns are drugs and software.

Both assets have extremely unusual properties. Software benefits from extremely low capital requirements and absurd margins. A small team with a great startup idea can run the YC gauntlet and achieve Internet-scale product growth on a continually accelerating time scale.

While drugs don’t pump out the steady Annual Recurring Revenue (ARR) streams that make SaaS VCs so happy, they have their own advantage—they are the highest-margin physical product in the world. Small molecules are incredibly cheap to produce, but are sold at extremely high prices during the life of their patent in order to recoup R&D costs and incentivize innovation. After the patent window expires, they are sold much closer to cost as generics.

Drugs are actually an information product. Massive businesses have been built around platform technologies for generating novel medicines. We’ve already spilled a lot of ink explaining why we are so excited about investing in these types of businesses at Not Boring. The intellectual property of a successful drug can be well worth the initial capital requirements for platform creation. This is why it makes economic sense for Varda to offer the first microgravity platform for therapeutic development.

While it sounds like science fiction, there is real demand for this platform. As Adrian came to realize, chemical matter behaves very differently in microgravity at the mesoscopic scale—that goldilocks range between the world of atoms and the macroscopic objects we interact with. One tangible example is the difference in natural convection, which is the process of heat transfer through the bulk movement of atoms together. Think of water, beginning to boil. As a heat gradient emerges, a convective pattern emerges where the hotter liquid becomes buoyant, and the colder liquid replaces it.

In microgravity, there is no buoyancy to create this pattern. Similarly, particles don’t clump together and settle out of liquid in the same way. Certain macroscopic physical processes are altered in ways that highlight these substantial mesoscopic differences. Candles are a widely used example of this absence of natural convection—the height of a candle flame is a function of the convective processes that aren’t present in microgravity.

Scientists have been taking advantage of these unique features of microgravity environments in space to create crystal structures of molecules. Crystallography is a central technique in the life sciences—it’s how we figured out the double helical structure of DNA and every single other molecular structure we’re currently aware of. Over the past few decades protein crystal growth (PCG) experiments have been “by far the largest single category of experiments conducted on the orbiting lab” of the ISS.

Early PCG experiments in space have produced remarkable results. In 2017, Merck conducted a mission on the ISS to explore the crystal properties of Keytruda®, their blockbuster cancer drug, in microgravity. Whereas the drug crystallizes in a bimodal distribution of 13 and 102 μm particles in terrestrial gravity, it forms a homogeneous distribution of 39 μm particles in space. The tight distribution of smaller particle sizes means that dosing patients correctly is much easier, so you can send them home with syringes they can self-administer, versus having to do IV dosing at the clinic every day.

This is just one axis of improvement for one antibody. Doing crystallization in space is like adding a gravity knob to your instrument—it opens up regions of process design space that would otherwise be inaccessible. Importantly, after the crystallization occurs in space, the drug retains its solid state upon re-entry. Manufacture in space; use on earth.

This is why pharma is going to space to experiment with a wide range of medicines. Formulations made in microgravity could open the door to improvements in drug shelf life, bioavailability, IP expansion, and even better approaches to drug delivery.

For Paul Reichert at Merck, the value proposition is clear: “I think there are a lot of microgravity research opportunities and I am going to continue to try to encourage people in diverse scientific areas to think about how they could benefit and learn from doing microgravity research.”

To date, there has been a major disconnect between microgravity research and manufacturing. While it’s been possible to hitch a ride to the ISS and collaborate with NASA on PCG experiments, there is no existing commercial offering to actually manufacture drugs in space. Merck used their research results on Keytruda® crystallization to tinker with their terrestrial approaches to formulation. What if they could actually just manufacture the crystals they discovered in microgravity at commercial scale?

This is Varda’s mission—to make widespread research and manufacturing in microgravity a reality. Riding the wave of commoditized launches to space, Varda is building the infrastructure to manufacture valuable chemical matter in space in partnership with leading pharma companies, and solving the reentry problem needed to recover the results.

Between the plummeting launch costs and the dual-use nature of each mission, the actual cost of space manufacturing would pale in comparison to the revenue that could be generated from a very small amount of chemical matter. For context, the active pharmaceutical ingredient in most drugs—what Varda is focused on producing—is a miniscule proportion of the final drug product delivered to patients.

As Delian likes to point out, “Two milk gallon jugs of mRNA would be sufficient for all of the Pfizer vaccine doses administered to date.”

Pfizer generated $76.4 billion in revenue from its COVID vaccine in 2021 and 2022. If you stacked all of that revenue in hundred dollar bills next to the milk jugs, they would reach 82 km above the earth’s surface, just below the Kàrmàn Line that marks the beginning of space.

With these characteristics, it’s hard to think of a better minimum viable product for space manufacturing.

While The Case for Space inspired Delian to start Varda, Zubrin was actually too conservative in his estimates around pharmaceutical manufacturing. Even at $5,000/kg launch costs, Varda can build a profitable business. Zubrin missed a few things.

First, the dual use nature of the business means that the DoD will cover a healthy portion of the costs of each flight on which they rideshare, effectively bringing down Varda’s out-of-pocket cost to manufacture drugs.

Second, the API in drugs can be much more valuable per kg than Zubrin gave them credit for. Pfizer’s COVID vaccine is an extreme example, but there are a number of small molecules that fetch hundreds of thousands or millions of dollars per kg, more than covering all of the launch and manufacturing costs:

To start, Varda is focusing on the identification of new polymorphs for small molecules. Over time, they are going to expand their platform offerings to support microgravity crystallization of larger molecules like Keytruda®. These drugs can fetch even higher prices per kg, reaching into the hundred-billion/kg range in one example:

Zubrin’s 40 ton target of the API in Blincyto, a leukemia immunotherapy drug, would be worth $4.5 quadrillion. Obviously, that’s absurd – there isn’t demand for 40 tons of Blincyto and the world’s economy couldn’t support the cost if there were – but it serves to illustrate just how much value pharmaceutical APIs can pack into each kg. They can be worth far, far more than their weight in gold.

Third, and critically, because Varda is the only company that can manufacture pharmaceuticals in microgravity, it can command economics in-line with cutting-edge platform companies, including upfront payments worth millions and “bio-bucks” – milestone payment and royalties – that could reach tens or hundreds of millions of dollars depending on the success of the drug.

Over time, as Varda scales and manufactures more drugs, it’s likely it will adopt a fee-for-service model that locks in significant upfront revenue at the expense of upside, but for now, it’s able to share in the success it helps create. And like a good platform company, Varda might one day decide to take advantage of its own technology and start bringing drugs to market itself.

Taken together, Varda has the ingredients to build a profitable business early in its life, which is insane when you remember that we’re talking about manufacturing drugs in space. But that’s the point. Delian has repeatedly stated that in order for humanity to expand beyond our planet, we need to do it like the Portuguese did, in a way that makes economic sense and incentivizes further expansion using the oldest trick in the book: money.

Start with high-value pharmaceuticals, then slowly expand as costs come down and space industrializes, until we can manufacture every material sensitive to the entropy caused by gravity in space.

On paper, it makes a lot of sense. But first, Varda needs to prove it can do it.

What to Expect from the First Mission

At 2:19pm PST this afternoon, a SpaceX Falcon 9 rocket will take off from Vandenberg Space Force Base in California. This isn’t so unique in and of itself. SpaceX has completed 238 total launches to date, and these days, it does about two launches every week.

What’s unique about this launch, the Transporter-8 Mission, is that for the first time, it will be bringing a standalone commercial space factory up with it.

You can watch the launch live on YouTube this afternoon when the launch window opens at 2:19pm PT:

Varda’s focus for this first flight will be on successfully re-entering the atmosphere and deploying parachutes for a safe landing in the Utah desert. Its second priority will be running tests on ritonavir, an HIV/AIDS treatment from the 1990s that needed to be reformulated because of stability issues related to the crystalline form of the drug. Showing that microgravity would have helped AbbVie avoid the need to reformulate Ritonavir would be a cherry on top, but as long as that capsule lands safely in Utah in mid-July, the first flight will be a success.

Here’s what to expect between now and July.

The launch window for SpaceX’s Transporter-8 million will open at 2:19pm PST this afternoon. The launch process will take 38 minutes total. With 3 seconds left, the engine ignition sequence starts. Then… liftoff.

One hour and 22 minutes into the flight, the payload, including Varda’s satellite and capsule, separates and begins its orbit around planet earth.

Varda’s spacecraft will orbit for a little over a month. This orbit will be longer than future orbits because it will be testing its systems for the first time, which will take the first week or so. It will then run tests on ritonavir for another week or so – heating it up and cooling it down to let the crystals snap into place.

Once the tests are complete, the spacecraft will orbit the earth while it waits for its re-entry window, which begins on July 17th. Re-entry is a complicated dance to orchestrate, involving the FAA, the US Air Force (on whose Utah Test and Training Range the capsule will land), and the spacecraft’s position in orbit.

On re-entry day, when the spacecraft is 1,150 km above Greenland, it will ignite its booster in the opposite direction of its orbit in order to slow down enough to fall out of orbit, or “deorbit.” At 500 km above the earth, somewhere over Canada, the capsule will separate from the satellite bus and begin its rapid descent down to the earth’s surface.

As it tumbles from the sky, it will reach speeds over Mach 25, or 19,000 miles per hour. As it hits thicker and thicker atmosphere, the capsule will stabilize and decelerate. At its peak, it will experience a 12 g deceleration.

The capsule will maintain hypersonic speeds (above Mach 5) until it’s 40 km above the earth and then slow to a leisurely 75 m/s at an altitude of 10 km. Then it will deploy its parachutes and float down to the desert ground at 5 m/s until it lands safely on the Utah Test and Training Range.

Once the capsule has landed, it will be recovered by military personnel and returned to Varda for post-flight testing and analysis.

If Varda is successful on this first mission, it will unlock the next stage of the company’s life. It is scheduled to fly its second mission later this year, and success in July would mean that it will be able to fly that mission with both commercial and government partners and begin generating real revenue. Failure on mission one would turn mission two into another demo mission.

But let’s assume success for now. With a successful mission under its belt, what does the future hold for Varda and the space economy?

Expanding the Economic Bounds of Humankind

Today is Day 874 in Varda’s journey, and it’s an incredibly important one.

In a few decades from now, we may look back on today as one of the key turning points in our species’ history in space. By the time we go to sleep tonight, the world’s first commercial space factory will likely be orbiting around our planet.

But it’s just the first step in the pursuit of the company’s mission to expand the economic bounds of humankind.

Achieving that mission will take decades or longer. The universe is a very large place. But the company’s goal for the next few years is clear: make space manufacturing routine.

Later this year, Varda plans to launch its first live mission with a pharma partner onboard. Next year, it will fly the first flight in its STRATFI program while continuing to sign pharma contracts and work with customers to identify which drugs to test and manufacture. The sweet spot is drugs that benefit the most from microgravity and have the highest commercial potential.

Certainly, Varda will face competition. As it stands today, there are companies performing commercial pharmaceutical research on the ISS, and others, like Redwire, have plans to do large-scale manufacturing in microgravity.

But if Varda is successful on this first mission, it’s going to have a very large head start. Already, it’s built the most sophisticated team in the space, hiring up one of the scarcest resources in the space: ex-SpaceX engineers. It would be very difficult for another company to build up the capabilities that Varda has in just over two years.

So many companies will look to outsource certain capabilities by working with commercial stations that companies like Blue Origin, Northrop Grumman, and Nanoracks have in the works. They’ll find challenges there, as well. Orbital Reef, a collaboration between Blue Origin, Sierra Space, Boeing, and Amazon, among others, will have capacity for up to ten crew. Because it’s important to keep them alive in the harsh conditions of space, astronauts are among the most expensive people in the world to employ. It will be difficult for crewed commercial stations to compete with Varda on cost, although crewed stations will be excellent for research on humans.

If competitors are able to successfully manufacture in space, they’ll run into the same speed bumps that Varda has in getting FAA approval for sending products back down. Early in the company’s life, Varda hired Eric’s ex-Zipline colleague, Dan Czerwonka, as General Counsel to head up regulatory affairs, and under his guidance, the company is likely to get through the FAA’s new reentry regime, Part 450. Here, too, the company has a head start.

What Varda does with that head start will make all the difference. And given the architecture of Varda’s business – the fact that it works so well for both government and commercial customers – Varda can build its lead with each flight.

As the pace of launches picks up, Varda will work to drive down the cost of each flight across a number of fronts:

Vertical integration. As Varda launches more frequent missions, it will make sense to leverage the skills of its engineering team and build more of the spacecraft’s components in-house.

Reusable reentry capsules. Varda will use the flight data it gets back on its first flights to make capsules that take down less product but are stronger and reusable.

More permanent manufacturing equipment. Over time, Varda will develop manufacturing equipment that looks less like a satellite and more like a space station. That will come with its own challenges – docking, maintenance, refueling, and propulsion among them – but can lower costs while allowing for more sophisticated manufacturing processes.

Ride the launch cost curve. As Starship comes online and Varda books rides in bulk, it should be able to dramatically lower its launch costs.

All-in, Varda expects that it will be able to decrease its bill of materials (BOM) by over 90% in the coming years.

Lower costs and more frequent launches set Varda’s flywheel spinning even more rapidly. The DoD will be able to purchase more reentry-as-a-service rideshares. The number of pharmaceuticals that make economic sense in space will grow. When space manufacturing becomes cheap enough, pharma companies may opt to manufacture drugs for which the benefits of microgravity are moderate but non-negligible, even as Varda develops the capabilities to partner on higher-value large molecules and biologics.

At that point, Varda will start to resemble a mix between terrestrial contract manufacturing and platform companies, but in space, with satellites and permanent manufacturing facilities heating, cooling, and crystallizing all manner of drugs, practically on-demand. Like a fast-growing industrial town, the sky will be dotted with factories.

When the Portuguese first ventured out into the Atlantic Ocean during the Age of Discovery, they too dealt in items that packed a lot of value into each kg, trading beads, spices, textiles, and horses for gold. Today, six centuries later, even the least valuable trinkets travel across the seas on ships built to carry commerce across the globe.

If Varda is wildly successful, it too will facilitate the manufacture and trade of increasingly low-value-per-weight items as space manufacturing becomes just another thing that humans do. Next up will likely be the other items on Zubrin’s list – fiber-optics and semiconductors made in space for use on earth. Advanced materials, organs, and all manner of things that inventive people dream up with a gravity knob at their disposal may come next.

As humanity travels off of earth to Mars, asteroids, the moons of Jupiter and Saturn, and beyond, it will seem quaint and silly that for millennia, we only knew how to make things on our home planet’s surface. “Space manufacturing,” one day, will just be called “manufacturing.” Humanity’s economic bounds will be contained only by the percentage of light speed we’re able to capture.

But that day is many years away. Today, let’s just marvel at the fact that we figured out how to fly and operate space factories. Ad fabricas inter stellas.

Thanks to Elliot for writing this with me, to Delian, Will, Eric, Adrian, and the Varda team for helping us get up to speed, and to Dan for editing.

That’s all for today. We’ll be back in your inbox on Friday for the Weekly Dose and we’ll be back on the summer schedule next Tuesday.

Thanks for reading,

Packy

This is truly incredible stuff. The mind-boggling concept, the speed of execution, and a successful government contract within 2 years. Reminds me of what made "Silicon Valley" a magical space for the "believers" and not the "corporate warriors looking for their next Pre-IPO career opportunity".

Superb! Reading this essay feels like glimpsing what Peter Thiel says - every great business is built on a secret (contrarian truth).