Cuby: The House Factory Factory

Building the Factories that Build the Homes to Fix the Housing Shortage

Welcome to the 595 newly Not Boring people who have joined us since last week! If you haven’t subscribed, join 232,820 smart, curious folks by subscribing here:

Today’s Not Boring is brought to you by… Attention

Sales is hard. Attention makes it a little easier.

Attention is an AI-powered call recorder trusted by sales teams at industry giants like Snowflake, Datadog, and Stripe.

Attention’s AI captures and analyzes every sales conversation, revealing how and why your deals succeed. It not only identifies winning strategies for your team but also empowers you to act on them.

With Attention, you can automate key workflows based on customer interactions: generate personalized follow-up emails after calls, populate your CRM with crucial deal information, alert stakeholders to potential churn risks, create coaching scorecards for your sales reps, send weekly executive reports on deal outcomes, and more.

Unlike other tools that merely provide insights, Attention delivers both insights and the actions needed to close more deals. Close more deals with Attention.

Hi friends 👋,

Happy Tuesday! This is why I get up in the morning. A Vertical Integrator tackling a trillion-dollar market to solve one of the developed world’s biggest challenges: housing.

Cuby is complex. I’ll admit, when Aleks Gampel, Cuby’s co-founder, first sent me the company’s data room as I was diligencing the company for Not Boring Capital, I was overwhelmed. Housing is as difficult to solve as it is important, and Aleks and his cofounder, Oleg Kandrashou, have thought through every piece of it in brain-breaking depth.

The more I dug in, though, the more fascinated I became. Every question I had was answered somewhere in that data room. Every reason experts gave me that something like Cuby might not work — labor, capital intensity, supply chain, local codes — was anticipated, and the solutions were baked into the core of the plan.

At the end of more than a month of research, I came away convinced that Cuby can build a very large and very impactful business. I decided to invest in Cuby, and to figure out how to wrangle all of that complexity into a Deep Dive.

If we can fix the housing shortage, we can fix anything. And I think Cuby is going to help fix it. This Deep Dive is my attempt to explain how.

For fun, I ran the Deep Dive through Google’s NotebookLM, which produces conversational podcasts with whatever you feed it. It’s pretty good for a quick overview!

But the beauty of Cuby is in the details. And for that, we need some more words.

Let’s get to it.

Cuby: The House Factory Factory

(Click the link 👆 to read the full Deep Dive online)

If you want to fix a problem as large and multivariate as the housing shortage, the key is to discover the bottleneck.

For housing specifically, there are plenty of candidates. NIMBYism. Zoning. Construction costs.

But the bottleneck in housing seems to be skilled labor. There are not enough skilled tradespeople to build as many homes as the country, and much of the developed world, needs.

A recent Association of General Contractors of America survey found that 88% of respondents had a hard time filling craft positions, and for each and every one of 21 specific crafts, more than 60% of respondents had a hard time finding people. Worse, 40% of the existing US construction workforce is set to retire over the next decade, and as is the case with so many critical blue-collar jobs in America, the younger generation is not trained to replace them.

A few summers ago, on a drive to New Jersey with Puja in the passenger seat and nine-month-old Devin asleep in the back, I don’t know why I remember this so vividly but I remember we stopped at a rest stop on the Jersey Turnpike and as we got ready to hit the road, we turned on a Planet Money podcast on the housing shortage.

In Blacksburg, Virginia, the focus of the episode, but really, across America, the hosts identified three culprits: old people weren’t moving out of their homes, NIMBYs were blocking development, and “the U.S. doesn’t have enough people who know how to build houses.”

Of the three problems, labor is the bottleneck. Solutions to the other two without skilled labor to actually build the houses get us nowhere.

Old people not moving out of their houses can be solved by building new houses. Many of the homes they live in were built in the post-World War II era, are becoming obsolete, and will need to be rebuilt anyway. And there are plenty of places unencumbered by NIMBYism where we’re still struggling to build houses; Las Vegas, for example, only built 11,000 homes last year, 83,000 short. They suffer from a lack of skilled labor.

If you want to fix housing, you need to fix the labor issue.

One of the keys to the solution is that while there is a shortage of skilled labor – thanks in part to young people not entering the industry and getting trained up post-Global Financial Crisis – there’s not a shortage of unskilled labor.

So how do you make it so easy to build a house that anyone can do it?

That’s the question that Cuby is trying to answer. It’s harder than it sounds.

To solve the skilled labor issue, and deliver high-quality homes faster and cheaper than traditional home builders can, which is what you need to do if you want real adoption, takes a system with so many pieces, so tightly connected – from hardware to software to logistics and supply chain to business model – that it’s hard to explain simply. I’ve written more drafts of this intro than for any other essay I’ve written.

Mercifully, Cuby has boiled it down to one Key Performance Indicator (KPI) that the whole machine that is the company works to grind down:

Output Per Mobile Micro-Factory (MMF) in Square Feet / Required (Skilled) Labor Hours

How much home can you build per unit of skilled labor?

There’s a lot to unpack in just that formula alone. Like, for example, what is a Mobile Micro-Factory?

Cuby’s product is a factory that makes homes. It is a tool that helps people build homes.

MMFs are “mobile” in that each one is sent to where homes are to be built.

MMFs are “micro” in that each is just 30,000 square feet and requires total land of about 195,000 square feet. For scale,each can fit in a mall parking lot – which are often between 500,000 to 1.5 million square feet – and pump out kits of parts for 200 homes per year.

There are very good reasons for both mobile and micro, informed by a history of failure in mechanizing home construction and rooted in principles of lean manufacturing, and we will explore them today.

What you need to know for now is that these MMFs, and the people in and around them, can produce high-quality homes for roughly $100 per square foot (much cheaper than traditional homebuilding) in 30 days (much faster than traditional homebuilding) using mostly unskilled labor. These homes look like normal homes. They’re customizable. And because they are customizable and look like normal homes, to both naked and trained eyes, they can be designed to meet local zoning laws and housing regulations wherever the MMF is shipped and deployed.

You should also know – because I hear you thinking “This must be punishingly capital intensive” – that Cuby licenses each MMF via Special Purpose Vehicles (SPVs) with local partner/operators, often developers, who put $10 million into the SPV, $6.5 million of which is upfront CapEx for an MMF that costs Cuby roughly $5.5 million to make. Then, Cuby receives an ongoing percentage of the revenue generated by each MMF at software-like margins.

This is only possible because MMFs are mobile (local developers use them to build homes in their communities), micro (smaller developers can afford them and sell their output), and because they can deliver homes faster and cheaper with less skilled labor. Each individual developer may be technologically curious in their personal life, but as a group, they only care about technology insofar as it helps them generate higher returns.

See how everything fits – the format of the MMF with its performance and financing – and you begin to get a sense of the intricately designed machine that Cuby is building: the business that makes the factories that make the homes.

What Cuby is not doing is reimagining what a home can be or how they should look. That doesn’t work. People – developers, lenders, regulators (inspectors), and end-consumers – want what they want. What it is doing is rethinking the process and delivery mechanism of building homes from the ground up.

Cuby is certainly not the first company to try to use technology to manufacture homes cheaper, faster, or with less labor. In Vertical Integrators: Part III, we talked about Katerra, which burned through $2 billion in its attempt to vertically integrate housing, and while Katerra was the most well-capitalized, it certainly wasn’t the only. Veev raised $646 million and reached a $1 billion valuation in February 2022, before going into bankruptcy less than two years later in November 2023 and getting acquired by Lennar. Dozens have ended in varying degrees of failure.

In an article on the demise of Katerra, Construction Dive’s Sebastian Obando wrote, “Usually what happens unfortunately, is that pioneers are oftentimes the losers. Then the other guys come behind it and figure out what they did wrong.”

My bet is that Cuby are “the other guys.”

They have proven that they can build a factory that builds houses faster and cheaper with unskilled labor. Oleg lives in one with his family! They have signed the first SPV contracts in America. They have done all of this – over 400,000 engineering hours in three years – on just $8.5 million raised, or roughly what Katerra burned in an average week over its six years.

Now, they need to “copy and paste” MMFs, and show that the results they’ve achieved in Eastern Europe are repeatable anywhere in the world.

Not Boring Capital recently invested in Cuby’s Series B, despite and because of all of the previous failed attempts, and because Cuby is exactly the kind of Vertical Integrator I love:

Integrate multiple cutting-edge-but-proven technologies.

Develop significant in-house capabilities across their stack.

Modularize commoditized components while controlling overall system integration.

Compete directly with incumbents.

Offer products that are better, faster, or cheaper (often all three).

You will see how tightly Cuby fits this definition as you read on, so tightly that reading it back, I’m sure studying Cuby, and speaking with its co-founders Oleg Kandrashou and Aleks Gampel, informed my definition of a Vertical Integrator in the first place.

But of course, being a Vertical Integrator isn’t a guarantee of success. If anything, it’s the harder path. Vertical Integrators seem insane until they seem obvious.

In Part IV of that series, I wrote that Vertical Integrators are mispriced because they’re like trading options, with less certainty. The formula is something like: Size of the Prize x Plan x Probability of Execution.

I think that’s actually a pretty good framework for this Deep Dive. So today, we’ll talk about the opportunity in fixing home construction, where others have fallen short, Cuby’s plan to win, and the probability of execution, which really, comes down to the founders.

If Cuby succeeds, it will build a $100 billion+ company within the next couple of decades – this is a long-term plan. More importantly, it will solve a problem so big and tangible to everyone that “BUILD MORE HOUSING” is one of the few issues that Kamala Harris and Donald Trump can agree on.

Home Construction: A Tantalizingly Large Market

There are few startup opportunities as tantalizingly large as home construction.

America alone spends nearly $1 trillion ($941.5 billion, to be exact, per the US Census Bureau) on residential construction every year. That number includes renovations on existing homes, but the $550 billion the country spent on new home construction alone ($421 billion on single family, $129 billion on multifamily) makes it one of the largest categories of spend on planet Earth, between “Agriculture” and “Software” on venture fund Fifty Years’ Progress Map.

That spend number undershoots the size of the opportunity, because as many houses as we’re building (1.5 million in 2023), we’re not building nearly enough. Realtor.com estimates that America alone faces a gap of 7.2 million homes, and the problem is not unique to this country.

A 2022 National Association of Homebuilders (NAHB) survey found that the average house to build a home in the US was $392,241.

If we were to wave a wand and do away with all of the zoning laws and labor shortages standing in the way of filling the gap and just build, those 7.2 million homes would cost a total of $2.8 trillion to construct.

That is two times larger than global pharmaceutical spend and more than three times larger than the Department of Defense’s 2025 budget.

The problem is even more tantalizing to ambitious entrepreneurs because homebuilding, or at least renovation, unlike drug development or F-16 manufacturing, is something that most people have experienced firsthand.

There’s not a single person who has interacted with the home construction industry and thought, “Well, damn, that was pretty much perfect,” and entrepreneurs are even less likely to see a process and think that there’s no way to improve upon it than the average person, and so when they get their first taste of the messy process that is homebuilding, they think to themselves, “I can fix this.”

Home construction in the US alone is a $1 trillion annual opportunity, with a nearly $3 trillion backlog. It is fragmented across thousands of local developers and home builders, and further fragmented across thousands of subcontractors. It is nearly always delayed and over budget. It is as close to the platonic ideal of a startup opportunity as defined by Keith Rabois as you can possibly get (which is, perhaps, why Rabois started Opendoor):

It gets even more tempting, from the perspective of an ambitious entrepreneur, because home construction as it stands isn’t constrained by the laws of physics, but, as discussed in the introduction, bottlenecked by a lack of skilled labor. Doing more with less is what technology is built to do! We have 3D printers, robots, new materials, and software. We should be able to fix this.

Even the government wants to fix this problem. I spoke with Miles, Evan, and Bobby Jo at Your Washington Office, a firm that works on government relations with frontier tech companies, and they told me that the policy tailwinds for housing are as strong as they’ve been in a long time. “We’re at a moment in time where both presidential candidates are referencing housing from their convention speech. Obama is driving a YIMBY message,” they explained. “Whoever wins, both Kamala and Trump will want to be the one who gets this done.”

It’s no wonder. Supply shortages drive rising costs, which means that the American Dream of home ownership jumps further and further out of reach every day the problem goes unsolved. A recent Morgan Stanley report noted that “Since 1990, housing affordability has worsened 3x.” Since 1984, the US House Sales Price to Income Ratio has jumped 5.8x. In just the past four years, Zillow found, the income required to afford an average home has increased 80%, from $59,000 to $106,000.

That is untenable.

Truly, if someone can figure out how to build high-quality homes faster, cheaper, and with less skilled labor, at scale, they will be met with near-bottomless demand, potentially even incentivized by the government.

Huge market. Supply shortages. Labor shortages. Skyrocketing prices. Political support.

Housing construction is a siren song.

You must keep clear of their voices, plug your comrades’ ears with sweet beeswax, lest any listen and be lured to ruin. – Homer’s Odyssey

This song has lured many an intrepid entrepreneur to their death, metaphorically at least.

A Brief History of Prefab and Manufactured Housing

Despite the size of the prize, there is no SpaceX of Home Construction.

In some ways, building houses that comply with local zoning and building codes (of which there are approximately 26,000 in the United States alone) in thousands of municipalities across the country, one at a time, is a harder problem to solve than building reusable rockets. With rockets, at least, you can put a team of the world’s best engineers in one place and vertically integrate as much as you need to get the job done. With rockets, you are your own main customer; the other customers you work with don’t need to live in your rocket, don’t need it customized to their personal preferences, don’t care if it feels like home as long as it gets their payload to orbit.

That hasn’t stopped a century’s worth of entrepreneurs from trying. To date, while some have had fleeting or niche success – Sears Kit Homes, Levittown, or Clayton Homes – not one has really solved the problem. Most have produced more lessons than homes.

That’s good! In Federalist No. 5, John Jay as Publius wrote of the British, “We may profit from their experience without paying the price which it cost them.” Cuby may profit from previous attempts’ experience, without paying the price which it cost them.

Which starts with the insight that strikes every aspiring home construction entrepreneur when they first enter the Idea Maze:

We should manufacture houses like we manufacture cars.

On its website, in bold yellow, housing construction startup Diamond Age proclaims, “What Henry Ford did for cars with the assembly line, Diamond Age does for homes.”

And it makes sense. Henry Ford figured out that assembly lines decrease costs over a century ago, and we’ve been riding his lessons to material abundance ever since. You and I wouldn’t be able to afford cars if Tesla had to send a team to our driveways to assemble the parts on-site. There would be no Moore’s Law if each chip had to be assembled one-at-a-time at the location of the computer it was going to serve.

No, centralized manufacturing is key. The benefits of manufacturing are manifold: efficiency, speed, cost, consistency, safety, precision, scalability, and even innovation. Manufacturing something lets you bring it down the learning curve: as you make more of the thing, you make it more cheaply.

If you want to apply the magic of the assembly line to homebuilding, there are broadly two approaches you can take:

Prefabricated Homes: Homes are assembled in sections or modules in a centralized factory, and then shipped onsite, where they’re assembled on a permanent foundation.

Manufactured Homes: Homes are built entirely in a factory, transported onsite on a steel chassis (which often stays in place), and then plopped onsite.

Manufactured homes are their own distinct category – they are cookie-cutter, often cheap, and they depreciate like cars do. These are not typical homes you’re thinking of when you think about a home – they’re built differently, face different regulations, and generally have a lower perceived value. There are some large manufactured homes companies, like Clayton Homes, which Berkshire Hathaway acquired for $1.7 billion in 2003, but they serve a specific niche, the low-end of the market.

Prefab homes are more similar to traditional site-built homes, with more customization available. You might see a prefab home and have no idea that it’s a prefab home. That’s what we’re after here — homes that look like homes, built better.

Prefab homes have been housing innovators’ White Whale since as early as the 1920s, when Buckminster Fuller created the Dymaxion House. Even Ford himself toyed with the idea.

A century later, it’s still an unsolved problem. Looking at Bucky’s Dymaxion – just looking at it – provides one clue as to why. Would you want to live in that?

Henry Ford himself could have told you the Dymaxion House would never work.

In his autobiography, My Life and Work, he writes: “Where most manufacturers find themselves quicker to make a change in the product than in the method of manufacturing – we follow exactly the opposite course. Our big changes have been in the methods of manufacturing.”

Buckminster Fuller, and scores of intrepid entrepreneurs since, have attempted to change the home to make it more manufacturable, instead of changing the method of manufacturing to match the task of building a home.

A decade after Bucky, no less an architectural eminence than Frank Lloyd Wright tried to design prefabricated, user-assembled homes. He called them Usonian Automatic Homes, and they were made of inexpensive concrete blocks that could be assembled in a variety of configurations. As this lovely website explains, “Wright hoped that home buyers could save money by building their own Usonian Automatic houses. But assembling the modular parts proved complicated, and most hired contractors to build their Usonian houses.”

None of these concepts reached scale, and none operate today.

So this is one lesson from the history of prefab housing: don’t change the house, change how you build it.

You can take standardization too far though. Projects like Levittown – entirely pre-planned developments of nearly identical homes manufactured on an assembly line and assembled in as little as one day – sprung up in the wake of WWII, as soldiers came home, started families, and, backstopped by the Veterans Administration and Federal Housing Administration, bought homes. When you think of a Pleasantville, the Technicolor 1950s neighborhood with perfectly identical perfect homes, you’re thinking of something like Levittown.

Levittown succeeded in building and installing a lot of affordable houses quickly. It failed in other important ways, like being racist and in the fact that the lack of diversity in the homes themselves fell out of favor as people shunned homogeneity in the 1960s and 1970s. Plus, there were concerns about how the quality of the homes themselves, and their sameness, would impact home values over time. We don’t really build Levittowns anymore.

So this is another lesson: customization is key.

This is true because people prefer not to sacrifice their personal preferences for affordability, and more practically, because each location is different. Local regulations and codes are different. Local tastes are different. Each individual site takes different shapes and grades.

So in the late 1990s and early 2000s, the “Prefab 1.0” movement reimagined the possibilities of prefabrication based on lessons from earlier attempts. Their goal was to deliver modern, stylish homes more efficiently and affordably, and they focused on aesthetics, sustainability, and customization to separate themselves from earlier prefab homes in buyers’ minds.

The question: could you give people homes they actually wanted to live in faster and cheaper by building components in factories?

The answer: kind of. Halfway. Almost. So, in short, no.

As Tom Chi, the Google X co-founder whose At One Ventures led Cuby’s Series A, explained to me, “The Prefab 1.0 movement realized a lot of wins. If you build a lot inside a covered facility, you don’t have construction delays from weather and people can be at a station in safe condition with their tools around them. You get a higher worker utilization per day, and a higher quality build at a lower cost.”

That’s the good half.

The problem, Tom said, is that they, “Achieved half the dream. They ended up getting a lot of elements pre-built. But you still needed to move the entire house’s worth of weight somewhere.”

What happened, in very broad strokes, is that Prefab 1.0 took a home that would have cost $500k site-built, actually built it for $350k in a centralized factory, but then needed to pay a ton of money to move the house in huge sections to the site and hired skilled labor to assemble it. Add in the fact that most players served just one piece in the value chain, and had someone else installing their components, which meant mistakes, rework, and long feedback loops, and all in, you ended up with something that cost maybe $650k, 30% more than site-built:

It was still manual labor, but putting it in a line setting produced real advantages on the build side. But the landed cost was higher, and a bit uncertain, because you were moving in huge housing sections, using double-wides and long beds, you’d need to cut down trees just to turn corners, some prefabs even needed heavy-lift helicopters to drop them in. That’s why it ballooned in cost.

This is a third lesson: logistics costs can kill prefab economics.

Brian Potter, the author of the best construction blog on the internet, Construction Physics, wrote an excellent piece on this titled Logistics, Production Volume, and Industrialized Building. He makes the case that whether factories should be centralized or decentralized comes down to product value density: the ratio of a product’s cost to its weight or volume. “The lower the density,” he explains, “the greater the relative fraction logistics costs (transportation, storage, etc.) are of overall cost.”

iPhones have high product value density, so they can be made in China and shipped around the world. Homes have low product density, so they need to be made near demand.

Because it costs what it costs to transport a shipping container over the same distance, as long as you’re within weight limits, shipping a 40-foot container full of tightly-packed 2x4s is more cost-effective than shipping a container with fully constructed wall panels or even rooms, which contain a lot of empty volume.

This is one of the reasons that so much of construction is just sending finished inputs (windows, doors, cabinetry, fixtures, flooring, and appliances) and non-finished inputs (like lumber, concrete, drywall, insulation, and roofing materials) to the site for local crews to take care of. Even still, the current process requires skilled labor to do messy, non-structured work to them even before install, resulting in mistakes, lots of rework, and waste. Building an average 2,000 square foot home generates four tons of waste!

Pre-fab 1.0 was stuck somewhere in between: higher logistics costs, a little less waste, a lot of on-site work and assembly. Paying so much on logistics and then paying skilled people to handle so much on-site makes the economics hard to pencil.

More than anything else, this is what killed Prefab 1.0.

Prefab 1.0 was almost a product in search of a problem. It was driven by new technology – Computer-Aided Design (CAD), Building Information Modeling (BIM), and Computer Numerical Control (CNC) Machines – and the belief that maybe, now, with these new technological tools, we might finally be able to realize the dream of doing to homes what Ford did to cars.

Cars, however, are different than homes. For one important thing, they are mobile: once assembled, you can drive them off the line. More efficiently, you can put a bunch of them on the back of one truck and carry them to the lot that will sell them to the customers who will drive them home. You don’t need to cut down trees or hire helicopters to get cars from the place they’re made to the place they’ll be used, nor do you have to do final assembly in the driveway, calling in teams of skilled professionals to snap their pieces into place, hook them up to plumbing, or connect their wires.

So here’s a fourth lesson: centralized gigafactories don’t work for home construction.

Expensive, centralized factories have a number of disadvantages: they require more capital and time to launch, before the process is perfected, feedback from the site takes longer, they can’t produce with specific local codes in mind, and you need to keep running the factory even when demand slows due to high fixed costs.

Above all else, if you build something for less in the factory, and pay more than you’ve saved to transport and assemble it, you increase costs. And increased costs don’t work.

If there’s one thing developers will not countenance, it’s adding cost. They like making money, and more contractually, they’re obligated to pay back the debt they take on to get each project going. The formula that drives them is:

Return on Investment = (Sale Price - Costs) / Costs

There are others, of course. They care about IRR and ROC and Profit Margin and Absorption Rate and Debt Service Coverage Ratio and Construction Cost per Square Foot and Sales Price per Square Foot and Inventory Turnover, not a single one of which improves with higher costs.

So this is a fifth, and maybe most important, lesson: don’t increase costs.

Which brings us to Katerra.

Katerra is worth studying on its own because it was the most well-funded, ambitious, and modern attempt to build a Vertical Integrator in housing construction. It fit the Vertical Integrator definition almost to a T. But that almost was the difference between a $100 billion outcome and $2 billion of (mostly) SoftBank’s money down the drain.

What Went Wrong at Katerra

I want to start this section, the last in our foraging of memory lane, by pointing out that this is not a knock on Katerra. The company was incredibly ambitious and full of people with more brains, talent, and experience than I have. This is just really hard.

In his retrospective on the company, Another Day in Katerradise, Potter, a former Katerra employee himself, writes: “At the time, I thought this was the exact right strategy needed to change the construction industry - it couldn’t be done piecemeal, it needed to be done all at once, simultaneously attacking every stage in the process.”

If I knew enough then, I’m sure I would have thought the same thing. Hindsight is 20/20. But that’s the point: each failed attempt brings us a step closer to the right one, if we learn the lessons.

Katerra’s founding insight seemed to be: previous attempts at fixing housing construction weren’t vertically integrated enough. Here’s Potter:

Instead of laboriously constructing buildings one at a time, by hand, buildings would be built the way everything else was built - prefabricated in a factory, designed specifically to be manufactured as efficiently as possible. Instead of designing buildings from scratch every single time, Katerra would have building products: standard, off the shelf buildings that could be customized for a client’s needs, the same way mass produced cars offer a wide variety of trim options.

This was the Katerra playbook when I joined the company. They would design a series of building products that could be mass-produced in their own factories, leveraging economies of scale and advanced manufacturing to build more efficiently than conventional construction. These products would be full of Katerra-supplied materials - everything from lightbulbs, to countertops, to bathroom fixtures, to appliances would all be Katerra brand. They would acquire general contractors in different markets to give them a nationwide construction footprint, and hire the various trades to self-perform all the construction work.

Katerra applied some of the lessons – don’t change the home, but don’t make them all the same – and seems to have ignored others – logistics can kill prefab economics, gigafactories don’t work, and ultimately, your fancy process cannot increase costs.

But maybe viewing Katerra as a housing construction company primarily is the wrong way to look at it. They may have primarily been a building materials company that used their prefabricated houses as a distribution channel and first and best customer.

As Potter explains, “They could (theoretically) afford to sell buildings for at or near cost, and simply use them as a vehicle to sell as many building materials as possible (similar to how manufactured home builders often make a large fraction of their profits from financing the homes).”

Because Katerra thought it had found a magical money glitch, and because it was oriented around selling materials that it had vertically integrated, it decided to offer a number of different products through which to sell materials: “But the economics of factory production still hold - making the numbers work requires maximizing your factory’s production volume. Katerra planned to do this with a series of standard, off-the-shelf buildings that it could prefabricate and sell all over the country.” Potter compiled a list of all of the different products that Katerra offered:

Katerra scaled and vertically integrated too much before it had a product that customers actually wanted to buy. They hadn’t figured out how to make prefab competitive with stick-built construction, which meant that there wasn’t enough demand for the “distribution” products to sell the actual products, the materials. It also meant that the company, though “pre-Product Market Fit,” was too large and unwieldy to iterate quickly to the right products and economics. “Ideally, early stage product development involves rapid iteration and prototyping, to figure out what needs to be built as quickly as possible,” Potter writes. “But the pace of product development at Katerra always felt sluggish.”

Here is one big lesson from Katerra: don’t vertically integrate too much, too early.

When I said that Katerra almost perfectly fit the definition of a vertical integrator, this is one of the things I was referring to. The third of five bullets in the definition is “Modularize commoditized components while controlling overall system integration.”

It seems as if Katerra tried to integrate commoditized components in an attempt to drive down their costs and make a margin on producing and selling them at volume. Which would make sense if the costs of those materials were the big bottleneck in home construction, but materials costs aren’t the biggest bottleneck in home construction. High materials costs may increase the cost of construction, but they don’t typically prevent homes from being built, and savings from cheaper materials can be overwhelmed by increases in logistics or labor costs.

So a second lesson: focus on the bottleneck.

Attempting to integrate relatively commoditized components comes with another disadvantage. One of the benefits of being a Vertical Integrator is that you can ride advances in certain inputs without locking yourself into any but the most critical to your system. Recall that Base Power Company “assembles and will soon manufacture battery packs itself, but it doesn’t make battery cells… Base believes that cells will be commoditized, and that pack assembly allows it to benefit from that commoditization and potentially integrate new cell types as better chemistries emerge.”

Katerra, on the other hand, locked itself into certain materials. One that Potter calls out specifically is cross-laminated timber, or CLT, a “super plywood.”

“Green technologies are enhancing our ability to create more sustainable solutions that also meet structural and aesthetic demands,” Nick Milestone, Katerra's director of mass timber, explained to Dezeen at the time. “Mass timber, and CLT in particular, is the only material grown for construction that offers incredible biophilic design solutions.”

The company spent around $100 million building out a plant to produce CLT, acquired high-end mass timber design talent, and could produce “something like 10% of the global supply of CLT, which required selling a LOT of it.”

Potter thought that the decision to make CLT manufacturing a part of the business model was smart for a number of reasons, including recruiting, separating Katerra’s products from the traditional view that prefab homes were “cheap,” and that with a push towards environmentally friendly materials, the company “could have been a major producer in an expanding market.”

Recall, however, that developers on the whole don’t give a flying fuck about green technologies or biophilic design solutions if those things drive up their costs without sufficiently driving up their revenues. The cost of the end product – the home – would have to be competitive in order for developers to buy it.

And too often, according to Potter, CLT was not cost-competitive: “CLT is an expensive product, and an easy target for value engineering if project costs are too high (we ended up seeing it get cut from a lot of projects).”

A specific lesson from Katerra’s CLT experiment might be: don’t bet your system on a specific, non-core component.

That’s easy to say in hindsight. It’s easy to see how you make that bet in the moment: if you’re right, you are the dominant producer and customer of an increasingly valuable input to one of the world’s largest markets. But the CLT bet was almost like adding Deep Tech risk to Vertical Integration risk, betting that this specific input would be better in the future as opposed to focusing on integrating based on the realities of the present.

It was kind of like adding leverage: amazing if you’re right, destructive if you’re wrong.

Katerra’s demise wasn’t solely, or maybe even primarily, due to its bet on CLT. Potter cited the slow pace of iteration, bloat from acquisitions, too much bureaucracy, and ultimately, lack of product-market fit, and noted that Katerra’s death was not inevitable: “It's easy to imagine that if one or two catastrophic things hadn’t happened, Katerra could have made it through, and become an amazing story of company survival.”

For his part, Katerra CEO Michael Marks gave a presentation in 2022 in which he said “the articles were all written saying we tried to do too much and the fact is we tried to do too little because we were doing all the hard work and the money was always going to the developer.”

Katerra, he argues, wasn’t vertically integrated enough! Just a little more vertical integration, and presumably a lot more money to support it, and we may all have been living in Katerra homes one day. This, by the way, is exactly what Marks is doing with his new business, Onx Homes: buy land, develop it, and vertically integrate the production of precast concrete homes.

Which brings up one last lesson: dial in your unit economics before scaling up.

The Lessons of History

That was a lot of history. I appreciate you sticking with me. I think it’s crucial to understand what went wrong in the past, why such an obvious idea as applying better technology and manufacturing processes to a $1 trillion market hasn’t produced any massive successes, in order to analyze whether Cuby has a shot at breaking the trend.

Just to catch our breath and make sure we’re all on the same page, here are the lessons:

Don’t change the house, change how you build it.

Customization is key.

Logistics costs can kill prefab economics.

Gigafactories don’t work for home construction.

Don’t increase costs.

Don’t vertically integrate too much too early.

Focus on the bottleneck.

Don’t bet your system on a specific, non-core component.

Dial in your unit economics before scaling up.

Learning from those lessons, Aleks told me that Cuby is making three bets:

Decentralized factories. Gigafactories don’t work. The factories themselves need to be shipped near-site, a hyper-local approach.

Don’t reinvent the home. Preferences from local incumbents, regulators/inspectors, and end-consumers (renters/owners) are hard to fight. Instead, change the process and delivery mechanism to be able to build any home faster and cheaper.

Don’t build Roadsters. You can’t start out more expensive than existing alternatives. Developers care about cost above all else.

Those bets are the framework – the Guiding Policy in the parlance of Richard Rumelt’s Good Strategy, Bad Strategy – on which Cuby has designed its many interconnected Coherent Actions.

The Cuby Plan

So you want to solve the labor bottleneck in construction and avoid the pitfalls that have ensnared all of the smart, well-meaning, and well-funded companies that came before.

Then you’re going to need to internalize a ton of complexity – just the right amount, at the right level of integration – and make it feel simple to the thousands of individual parties involved in the process.

Cuby’s goal is to help others build as many square feet of housing as they can with as few hours of skilled labor as possible.

The first question to ask, the answer which is not as obvious as it seems, is what product it’s building to achieve that goal. If early prefab companies’ products were homes, and Katerra’s product was materials, Cuby’s product is Mobile Micro-Factories™ (MMFs).

“Our product is the factories that move to the construction site, and using local materials and local labor, begin to produce this kit of parts, deliver it onsite, and assemble it onsite. That’s why each factory can produce roughly a house per day.”

This is how Oleg described MMFs in the intro to Jason Carman’s excellent S3 episode on the company, This Guy is Mass Producing Factories to Build Houses.

To really get a tangible sense for what Cuby is building, and how, I highly recommend you take the nine minutes to watch the video, which was shot remotely with Oleg onsite in Belarus and Jason in his earbud from California. Oleg explains a lot of the process better than I can.

That doesn’t mean I won’t try.

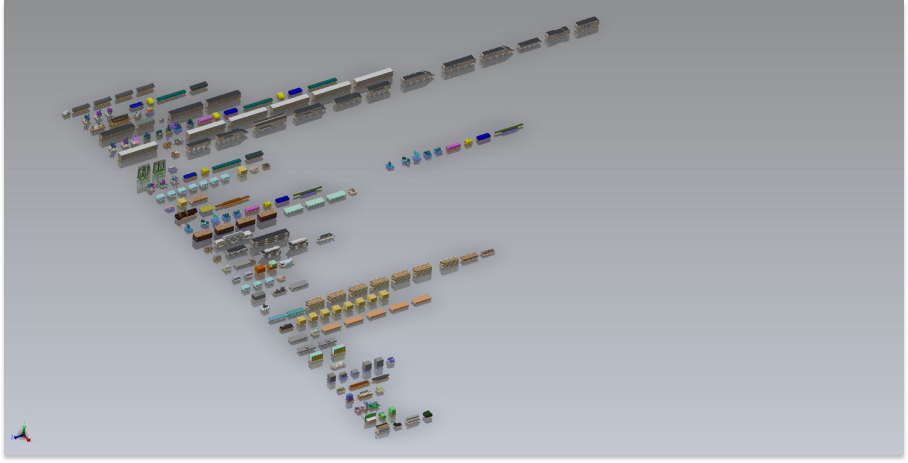

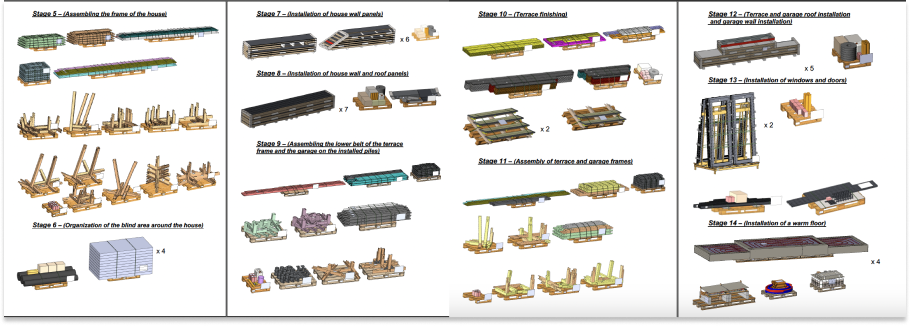

The most important thing to understand about Cuby is that it produces MMFs, finances them with local partners (often, but not necessarily, developers/homebuilders), and ships them to where the houses are going to be built. These MMFs produce 37 stages of kits of parts, or PAX, that are then flat-packed and trucked to the construction site, just-in-time, where unskilled workers follow detailed, auto-generated instructions to assemble homes in 30 days, for roughly $100 per square foot.

It, too, wants to do to housing what Ford did to cars, or more precisely what Toyota did to cars. It just thinks previous attempts didn’t apply the Toyota Production System properly.

“Lean manufacturing has worked everywhere else,” Aleks explained, “Why not in construction?”

The answer, Cuby believes and we have learned, is the distance between the factory and the construction site. Instead of selling parts into the existing system from a centralized gigafactory, and then watching savings disappear in logistics and skilled on-site assembly, Cuby controls the whole system, producing multiple MMFs, putting them near demand, and extending the lean manufacturing process from nearsite to onsite.

Here’s how it works.

Each MMF is essentially a pop-up factory that looks like a tennis bubble enveloped by custom shipping containers stuffed with equipment and that can be quickly deployed near construction sites or demand pools. They're designed to service a 150-mile radius, enough volume to keep the factory humming for years, but close enough that logistics costs don’t eat efficiency gains, and that the factory can take feedback from local sites and respond in time. If assembly on-site falls behind by a few steps one day, for example, the MMF won’t ship the next day’s components until it’s ready.

Essentially, what the MMF does is take in raw materials – wood, steel, pipes, glass, etc … (600 SKUs to be exact) – and turn them into kits of parts, or PAX, which are packaged, flat-packed, and trucked to sites in 37 stages, just in time.

Each PAX contains precision-machined components that are compact enough to transport efficiently and simple enough to assemble that most of the onsite work can be done by unskilled labor.

The PAX include:

Components made from scratch (like windows, structural framing, helical pier foundations systems, or non-structural insulated sandwich panels, etc.)

Prepared materials (pre-cut drywall, PVC pipes, electrical wires, etc.)

Distributed items (cabinetry, lighting fixtures, toilets, etc.)

Within each MMF, there are dozens of stations, machines, and robots, about half of which Cuby buys off the shelf, and half of which it had to design itself (aka proprietary). A few examples, of roughly forty stations, include “Insulated Glass Unit Manufacturing Station,” “Stud Cutting Post,” “Pile Welding Post,” “Wall Module Assembly Section,” and “Door Panel With Frame Assembly Section.” Over three hundred machines and tools operate across these forty stations in each MMF.

Roughly 100 workers, most of whom are unskilled, operate each MMF, each operating specific stations by following lean manufacturing principles. Each station has a Kanban Board, which flags whether a workflow stage is “To Do,” “In Progress,” or “Done.” Individual tasks are represented as cards that move across the board as they progress, and any employee can raise a flag when they need assistance (this is done physically and as a digital-twin in the software). An additional 160 work across 20 different on-site home builds (20 homes per month around the MMF, with four unskilled laborers in two shifts on each).

Everything – in the MMF and onsite – has its proper place and label, down to Cuby’s custom-made tool boxes, in which each tool has its own slot, and each box of screw or nails has a card that employees can throw up when they need a refill. It’s meant to keep the whole process running smoothly, even when most of the process is being run by people who haven’t worked in factories before thanks to Cuby’s MMF Operating System.

What specifically goes into each PAX (and when) is determined by Cuby’s software, which takes in architectural drawings – to figure out which components are needed for which homes – and supply chain information – sometimes, materials are brought in from China in containers (cheapest), and sometimes they come from the local Home Depot (most flexible) – and spits out custom instructions to produce each home’s PAX.

Parts are then organized into up to 37 PAX. Each PAX contains everything needed for a specific phase of the build of a home, packed in the exact order it will be needed on site (e.g., Stage 3, Pax 3 – installation of screwpiles for the foundation). Cuby has built software that fully automates decision making for the order of operations based on push and pull of tasks.

At the beginning of each home project, Cuby dispatches batches of equipment to the construction site, creating what's essentially a mobile extension of the MMF. This includes things like specialized tools, safety equipment, and even amenities for workers. The goal is to make the on-site assembly process as efficient and comfortable as the factory environment.

As construction begins and progresses, PAX are trucked to each job site, two at a time, just in time (JIT). On site, a team of just four unskilled laborers, working in two shifts, can assemble a home in about 30 days. They're guided by Cuby software, which uses Unreal Engine to auto-generate step-by-step 3D instructions for each task. It's like following a very sophisticated LEGO manual, but for a full-sized house, capable of dynamically changing based on the home that is being built.

These instructions go both ways – based on their completion, they trigger tasks in the MMF. Everything is push and pull, cause and effect, a multivariate equation updating in real-time.

This is one of the ways that Cuby is able to reduce the need for skilled labor. By owning the full process, it produces components that are easy to assemble, organizes them and ships them to the site in the correct order, and then provides step-by-step instructions. Since up to 70% of the cost of building a home is labor, and since skilled tradespeople are in such short supply, this is critical to Cuby’s ability to deliver homes at all, and to deliver them for less than traditional construction.

That doesn’t mean that there is no skilled labor, just that Cuby’s system is designed to only use skilled labor when it’s really needed. Tom Chi compares Cuby’s evolution of the construction process to the evolution of the copy machine industry.

Back in the day, if your copy machine had an issue, your company would wait, slightly crippled, for the manufacturer to send a copy repairman. Maybe they’d get there next Thursday, and usually, when they did, they’d just remove a paper jam and be on their way. Even something as simple as a paper jam had to be handled by skilled professionals because the jam was somewhere deep in the guts of the system.

Eventually, companies like HP and Epson realized that this was the worst part of the user experience, and they redesigned the paper flow to be user serviceable. Now, when there was a jam, the machine would flash the little instruction popup and guide users on how to fix it themselves. Sometimes, you’d still need to call in the pros for real issues, but most of the time, the user could fix the thing and get on with their work.

That’s how Cuby operates, too, both in the MMFs and onsite. For most things, Cuby’s process design and software make it easy for unskilled labor to complete and troubleshoot tasks. When someone with particular skills is really needed, someone raises a flag, and the pros swoop in.

“At the end of the day,” he explained, “one electrician can walk through and approve eleven houses, and fix the little things that only a trained electrician can fix.”

The whole system is designed to build high-quality homes that are responsive to customer needs, local codes, and supply chains in less time, for less money, with less skilled labor:

Speed: A 30-day production cycle is significantly faster than traditional construction methods, which can take 6-12 months for a similar home. Even if Cuby is off by 2x or 3x, it’s a massive improvement to the status quo.

Cost: Cuby claims they can build at around $100 per square foot based on their model units, which is competitive with or below what top production homebuilders can achieve, despite their massive scale advantages.

Quality: By using steel framing and non-structural insulated sandwich panels, Cuby can produce homes that are more durable and energy-efficient than typical stick-built houses.

Labor Efficiency: This is the bottleneck that everything is designed to solve.

Customization: Despite the standardized process, Cuby's system allows for hundreds of permutations in terms of size, layout, and finishes.

The result is a product that looks and feels like a traditional home - compliant with standard building codes and using familiar materials - but is produced in a way that's more akin to advanced manufacturing than traditional construction, with simple process and delivery mechanism improvements.

Here’s the latest home Cuby built in Eastern Europe, with zero skilled labor:

And here are some examples of the variety of homes and finishes Cuby can offer:

Customization is key. Customization at scale drives Cuby’s model.

Each MMF can produce roughly 200 homes per year, and Cuby’s goal is to produce 20 MMFs per year within the next few years, then 50 MMFs per year, so that in 10 years or so, there are 275 MMFs operating throughout the United States and the world that will “deliver 200,000 homes, create 100,000 direct jobs, remove 755,000 tons of waste that otherwise would have been generated on typical construction sites, and reduce 2.2 million tons of CO2.”

The whole process has been designed with this scale in mind from the beginning. Cuby has one operating MMF – the first of a kind, or FOAK, facility in Belarus. It has produced homes – including the one that Oleg lives in – for as little as $35 per square foot, thanks to the low cost of unskilled labor in Eastern Europe (It’s $97 adjusting for US costs). Even skilled and technical talent is cheaper there, which means that Cuby has built all of this – from initial design to manufacturing, over 400,000 engineering hours – on just $8.5 million of outside capital.

The company is also underway on several model homes across the US, including Commerce Township in Michigan, which should deliver first. These are built out of Cuby’s MMF in Eastern Europe and shipped over in PAX, meant to display what the end product can look like, if not the whole optimized process.

Cuby needed to get the first product, and the process, just right, in order to start the Kaizen of making small improvements that will add up over time.

Abdo Hajj from Type One Ventures, which led Cuby's Series B, believes that Cuby is ready to scale.

“There are very few companies in the world that have the capital efficiency and continuous technology improvements that I’ve seen in Cuby. This achievement is unprecedented,” he told me. “We are not concerned as to whether or not the MMFs will work; we want to help scale them. This will go down in history.”

Now, the goal is to “copy and paste” MMFs across the globe, to produce homes for $100 per square foot anywhere in the world, and then for less cost, at higher quality, with less skilled labor.

Sweating the Details

We’ll get to how they plan to pull that off, and whether they can, shortly, but after re-reading that last section, my attempt to do justice to the system that Cuby is building as simply as possible, I’m afraid that it’s neither very simple nor does it do justice.

Here’s my attempt at simple: Cuby builds Mobile-Micro Factories that produce components for homes, trucks those components to the construction site within 150 miles, and guides mostly unskilled labor in assembling them into a home that looks like a regular home, is customizable, and complies with local zoning regulations in 30 days, for $100 per square foot.

But that simplicity, even the expanded simplicity of the last section, obscures so much of the genius of the system, which only becomes evident as you peel back the layers, dive into how each one feeds the other.

Tom Chi, a formidable engineer himself, told me that “Oleg is an engineer’s engineer, someone who makes other engineers go, ‘Oh that’s fucking brilliant.’”

I’m not an engineer, but I know what he means. Every time I dive a level deeper into Cuby’s system – from the business model to the MMFs to the software – I discover things that make me say, “Oh, that’s fucking brilliant.”

So maybe I’ll just zoom in on three particular examples so you can see the level of detail at work:

Payroll, Unskilled Labor, and Quants

Mall Parking Lots

Synthetically Asset Light

Payroll, Unskilled Labor, and Quants

The first example is about how they knocked out my two biggest concerns in one shot.

I first heard of Cuby when its Oleg and Aleks went on my friend Christian Keil’s podcast, First Principles. I was impressed, but two things in particular scared me about the plan:

The Payroll System. As Katerra learned, there is such a thing as too much vertical integration. With so many problems to solve, and so many payroll systems available off-the-shelf, building their own felt unfocused.

Unskilled Labor. Even the most beautifully designed machines are limited by their weakest point. I thought what Cuby had designed was brilliant, but at the end of the day, it came down to relying on thousands of unskilled laborers on-site. At the very least, there would be variability in their ability and speed, and at worst, unreliability could kill a project.

Turns out, one worry is a solve for the other. Here’s how.

Cuby plans to employ four unskilled laborers, in two shifts a day, to build houses from the kit of parts that it makes and assembles in its Mobile Micro-Factories (MMF). It divides the construction process into 30 stages, each with three tasks. Each task has a specific “quant” - a measurable unit of work - with an associated time and price. Workers can follow step-by-step guides, automatically generated from plans using Unreal Engine, to complete the tasks.

Here’s what one step might look like:

And here are a bunch of steps strung together, to give you a better sense of the process:

It’s like IKEA furniture with dynamic, interactive instructions and no Swedish words.

Instead of paying workers hourly, Cuby pays them based on the quants of the tasks completed. When workers complete a task, they push a button in Cuby’s app, and after three tasks, a supervisor checks the work to confirm satisfactory completion. Once confirmed, payment is automatically sent to the worker’s account.

The system gives unskilled workers the potential to earn more money for doing good work, gives Cuby the ability to scalably manage a growing workforce of unskilled workers, and provides Cuby with granular data on every step of the process, which it might use to automate more of the processes over time. Genius.

Mall Parking Lots

The second example isn’t even one that Aleks and Oleg brought up, despite the many, many hours we’ve spent discussing the company. This one comes from Tom Chi.

“Cuby has found a way to reactivate a bunch of dead American infrastructure,” Tom told me.

For the past 50 or so years, American retail commerce was centered around the shopping mall. I grew up in Pennsylvania, 15 minutes from King of Prussia, the second largest mall in the country after Minnesota’s Mall of America (and the largest, I’d like to point out, if you don’t include their amusement park), so I know this as well as anyone.

On the many, many days that my friends and I spent at the mall, we’d arrange to have our parents drop us off at one of the department stores that served as entry points: Bloomingdale’s, Nordstrom, JCPenney, Sears, Neiman Marcus, or Lord & Taylor.

Now, if not at King of Prussia, which is really an excellent mall, then at malls around the country, many of these anchor stores, and the parking lots where millions of parents dropped their kids off and parked themselves, sit empty. We’ve all seen the creepy abandoned mall pictures:

Those underutilized mall anchor parking lots are ideal locations for MMFs.

“Cuby can approach these folks and say, ‘You have a big empty parking lot, we only need 50 x 100 meters, can we rent it from you?’ It’s a no-brainer,” Tom said.

What’s smart about mall siting is that malls are where they are for a reason: they’re always near highways, and always near a ton of residential neighborhoods. The mall needs easy ways to get products in and out, and needs to make it easy for as many customers to shop there as possible.

Cuby can set up MMFs in mall parking lots, get a ton of materials trucked in, and get the manufactured components out to residential construction sites quickly. It can operate in a tight radius with no special equipment; its PAX are designed so that each one can fit on the back of a semi truck, and if needed, a whole house could be delivered in a day.

This approach wouldn’t make sense for a gigafactory, but it certainly works for an MMF.

Synthetically Asset Light

The third detail is one that I touched on earlier, but that I need to expand, because it’s simultaneously only possible because of the model, key to the model, and proof of the value that the model can deliver.

Cuby’s mission is to “Empower others to build a better physical world.” Others is an operative word here, because what Cuby is building is a tool that developers and home builders – at first, the roughly half of the market comprised of non-publicly traded big production home builders like D.R. Horton, Lennar, and PulteGroup (the one so valuable it funds that weird Inventor of Twitter Philanthropy) – can use to build homes.

Each MMF sits in its own Special Purpose Vehicle, which partners capitalize at $10 million, $6.5 million of which goes to pay for the MMF, and $3.5 million of which funds operations (i.e., initial working capital and shortfall). It costs Cuby $5.5 million to produce an MMF, and the SPV is funded upfront, so it is cashflow positive and profitable on each MMF before it builds. Then, depending on the deal, it earns roughly 10-20% of the offtake price of each of the up to 200 homes the MMF produces every year for up to 10 years. That can mean $50-70 million of high-margin revenue over the life of each MMF.

This model is clever for a few reasons. By partnering with local operators and setting up each MMF as its own entity, Cuby can:

Scale rapidly without having to fund and operate every MMF themselves, reducing overhead and capital requirements.

Leverage local knowledge and relationships, crucial in an industry where, as Potter notes, "Different geographies will have different permitting jurisdictions, which may have different code requirements, different building departments with different levels of stringency, and different inspectors who care about different things."

Create multiple revenue streams: the upfront sale of the MMF, the ongoing cut of GMV, and potential upside from their equity stake in each SPV.

Align incentives between Cuby and their partners, ensuring both are motivated to make each MMF as successful as possible.

Focus on improving their core technology and processes, while leaving much of the day-to-day operations to local partners who understand their markets.

This is only possible because of the model: plenty of developers can afford to buy a $10 million tool that helps them produce homes faster and cheaper where they operate, very few can afford to fund a gigafactory hundreds or thousands of miles away from them.

It is key to the model: whereas previous prefab companies, most notably Katerra, consumed mountains of cash to vertically integrate and get to scale, Cuby is synthetically asset light. It maintains the control over the system needed to properly vertically integrate without having to put up the capital required to scale.

And it’s proof of the value the model can deliver: again, developers don’t spend money on technology for fun. They do it only if the technology can save them costs. That developers are signing deals with Cuby – the first, in Las Vegas, just went into contract – shows that they believe they will get enough cost savings from MMFs to justify the spend.

I spoke with Cuby’s partners on the Las Vegas MMF, Greg Palivos and Alex Samoylovich, and they told me that the decision came down to three factors: time savings, labor issues, and cost.

“Time,” they said, “should not be an issue. We’re talking about beating our timeframe significantly. And our labor issues are eliminated.”

They’re giving Cuby leeway on cost, recognizing that the first US MMF might start right below where they build today – around $140 per square foot – and come down to $100 per square foot with reps.

To start, they’ll get a faster build without the concern of finding enough skilled labor at the same price. Over time, they’ll get faster and cheaper builds, with less skilled labor. And Cuby’s margin comes out of Alex and Greg’s cost savings, so it’s a no-brainer: “Our interests are aligned.”

That’s an important point: Cuby can’t just sell a bunch of MMFs that don’t deliver. Over time, obviously, that would mean that no one would purchase SPVs, but even in the short-term, Cuby benefits financially from driving down costs. It gets the upside from strong performance without the CapEx risk.

Alex and Greg told me that Las Vegas has that 83,000 home shortage, and they want to do their part in filling it. “If it goes well,” Alex said, “we’d need to open more than one manufacturing facility in Nevada. We’d love to deliver 1,000 units consistently for 5-9 years.”

That sentence says it all: Size of the Prize x Plan x Probability of Execution.

Demand is practically bottomless. The plan makes sense, even to customers who are putting their own capital on the line. The open item is: “if it goes well.”

Probability of Execution

In Vertical Integrators, Part IV, when discussing how to assess the probability of execution, I wrote: “Here we are roughly 22,000 words into this series on Vertical Integrators and I’m about to write something incredibly anticlimactic: it all comes down to the founders.”

Well here we are again, ~10,000 words into a Deep Dive on Cuby, and reaching the same anticlimactic fork in the road: it all comes down to the founders.

The Size of the Prize Cuby is pursuing is massive: if it delivers the 275 MMFs it plans to over the next decade, it will make barely a dent in housing demand while generating $15 billion in annual revenue at 20-25% EBITDA margins.

The Plan, as I’ve tried to express both by studying the history of prefab and the details of Cuby’s business machine, is as intricate and thoughtful as any I’ve encountered at this early stage.

The value proposition to customers – mainly developers for now – is incredibly clear and compelling. If you can halve the cost to build a home, you can double or triple a developer’s margins.

And I think the Probability of Execution, with Oleg and Aleks at the helm, is surprisingly high.

Cuby has been in the works for five years and operating for three. In that time, and with only $8.5 million, they have designed and built a product, and signed the first contract (with multiple in late stages).

At this point, most of the pieces of Cuby’s system are somewhere around Technical Readiness Level (TRL) 7 - System Prototype Demonstration in an Operational Environment - or 8 - Actual System Completed and Qualified Through Test and Demonstration.

TRL was developed at NASA in 1974, and expanded from 7 levels to 9 in the 1990s, while Dan Goldin was the NASA Administrator. Goldin brought the “faster, better, cheaper” philosophy to NASA, cutting development time by 40% and costs by two-thirds. Unsurprisingly, Goldin is an avid supporter of Cuby’s mission and approach to the problem.

Tom Chi told me that “there is no team in our portfolio that has derisked so much per dollar.”

So the question is not whether they can build it, or whether they can drive lower costs on one MMF – they’ve already done that with unskilled labor in Belarus – but whether that will translate to the US market, and then, whether they can scale.

Having spent so much time with Oleg and Aleks directly, and talking to people around them, I strongly believe that they can. They’re a perfect co-founding team for the product they’re trying to build. There is a clear separation of responsibilities, and both are truly exceptional at what they contribute.

Aleks studied to be an engineer, and then went into real estate and finance. Before Cuby, Aleks worked on the real estate team at WeWork. He has both seen what it takes to scale violently with the wrong cost of capital, and the dangers of doing so without focusing on costs. Post-WeWork, he worked in real estate private equity, where he was searching for solutions like Cuby’s in order to improve his development’s yields, met everyone, and found nothing that he believed in when a family friend introduced him to Oleg. After their first couple of conversations, he quit his PE job to join Oleg in co-founding Cuby.

For a business that relies so heavily on properly capitalizing the business, and on complicated long-term partnerships, there are very few people as skilled or gifted as Aleks.

Oleg is a practical mad genius. Prior to Cuby, he ran a hardware product design and development company, Encata, that works with deep tech companies to engineer and manufacture their products, bring them to life, and commercialize them at scale.

A huge reason that Cuby has been able to do so much on so little outside capital is that Oleg brought over a team of more than 100 of EnCata’s best people in Belarus – where the talent/cost ratio is exceptionally high - and put them to work on executing everything from software to hardware. It helped to have access to EnCata’s millions of dollars worth of equipment and machinery. It works so well because he’s worked with this team before, and because he is able to hold the whole Cuby machine in his head and assign people to specific tasks needed to technically derisk the product by making it real.

One of the characteristics of a truly exceptional founder is the “Ability to hold the whole system in their heads, from 30,000 feet to one inch.” I have met very few people – maybe none – who do that as well as Oleg. There is not a question you can ask him about Cuby’s system that he couldn’t speak about for hours, something I’ve learned in my own conversations and in watching recordings of customer conversations. As Tom said, he’s an engineer’s engineer.

He’s also the author of The Human Vector, a book that lays out a philosophy for company building, management, and life that infuses Cuby. Oleg applies the same level of rigor to how he builds and manages companies as he does to the products and processes themselves.

Oleg and Aleks are a big reason I invested in Cuby and am so invested in its success, but for that reason, you might not want to take my word for it. Fair.

For the technical perspective, from someone who’s been there before, I spoke with the former CTO of Diamond Age (the company I mentioned earlier that planned to do what Ford did to cars, to homes), Russell Varone.

Russell was previously Tesla’s Director of Powertrain Manufacturing and then of General Assembly, which is to say, Diamond Age didn’t suffer from lack of talent, or from lack of automotive manufacturing know-how. It just took the wrong approach, at first trying to 3D print houses before realizing that wouldn’t work and pivoting to Light Steel Gauge framing.

Russell told me that when an investor friend asked him for help diligencing Cuby, and he dug in, he realized that theirs was the right approach. “They’re going to do it,” he told me simply, before adding a note on why that matters: “I structurally believe that if you put enough housing in the market, the country gets two letter grades better.”

Jason Carman, whose Cuby video you watched earlier, has created documentaries on more than 50 of the most compelling technology companies in the world. A few months ago, when we were chatting about something else, before I’d invested in Cuby, I asked him which founders he’d been most impressed by in his first year of S3.

He mentioned two companies, one of which was Cuby.

When I texted him this weekend to ask why he’d picked Aleks and Oleg, he replied: “No nonsense financial approach, Aleks has good knowledge and doesn’t have the Silicon Valley mind worm of over saturated VC funding and Oleg is a killer. They’re also cost obsessed.”

That summarizes it nicely. Oleg and Aleks are here to build a business and a product that work, and that can make a dent in the 7 million home shortage in the US. Both care about building a system that works, both are practically allergic to overspending, and both deeply understand the importance of driving down costs.

Maybe nothing captures what I’m trying to say more than this anecdote.

When Tom Chi started talking to Oleg and Aleks before their Series A in early 2023, they told him that the average cost to build a home was around $220 per square foot, and they planned to get it down to $150. By the time they started talking about their Series B, they’d already “blown past it. They were down to $110, it totally blows peoples’ minds.” Tom said that they weren’t even planning to get to $110, that “the intellectual metabolics of the team are just like that.”

“It’s rare,” he said, “that the quality of thinking is so good at every level.”

That doesn’t mean that there won’t be challenges. There will definitely be challenges. This has been one of the hardest opportunities in the world for even very smart people to crack.

It just means that Cuby has thought of most of them, and has designed the system to overcome them. Let’s go over a few of the foreseeable ones.

Regulatory Hurdles

One of the biggest obstacles for any new entrant in the construction industry is navigating the complex web of building codes, zoning laws, and local regulations.

Cuby's approach to this challenge is twofold:

First, their partnership model allows them to leverage local expertise. Their partners, who are often established players in their markets, bring valuable knowledge of local regulations and relationships with key stakeholders.

Second, Cuby has designed their homes to be IBC (International Building Code) compliant from the start, with small tweaks, if any, to the system to be applicable to any of the 26,000 zoning codes across the US without any major hurdles. By using familiar materials and construction methods, they're making it easier for local inspectors and building departments to approve their projects. In other words, Cuby does not want to be perceived as a technology innovator to the naked eye who is approving their construction drawing sets or inspecting their homes.

As Oleg put it, "We did not reinvent the wheel but made it spin faster. This is not about reinventing the end product (uncertainty and regulation are not a winning formula in this space); this is about changing the delivery mechanism and creating process improvements."

Industry Inertia

The construction industry is notoriously slow to adopt new technologies and methods. Builders, contractors, and even homebuyers often prefer tried-and-true methods over novel approaches, no matter how promising. This is one of the things that worried me most, having worked in real estate tech.

This seems to be a perfect time for a solution like Cuby’s thanks to the confluence of the housing shortage, construction climate concerns, the resurgence of investment in Vertical Integrators, technological tailwinds, and policy alignment. Even still, tailwinds don’t sell themselves; Cuby actually needs to get developers to partner on MMFs.

Cuby's strategy here is to focus on familiarity and cost savings. Their homes look and feel like traditional construction, but they're built faster and potentially cheaper. By offering asymmetric upside (significant cost savings) for minimal perceived risk, they're creating a strong incentive for adoption.

As a proof point, I watched a DD call with a Colorado-based developer Cuby provided, in which the developer’s builder asked a lot of questions about Cuby’s ability to deliver the type of projects customers in, say, Wisconsin, would want. When I asked Aleks what came of that conversation, he told me they’d just signed a term sheet with the developer.

To win in this space, you have to offer unit economics that someone cannot ignore.

Supply Chain Complexity

Managing the supply chain for a nationwide network of MMFs could be a logistical nightmare. Cuby has turned this potential weakness into a strength. While Cuby sources materials from China at very low costs, their MMFs are designed to also use locally available materials wherever possible, reducing their dependence on complex supply chains. There are benefits to non-proprietary supply chains, particularly before massive scale.

As another example of Cuby’s in-house software, Oleg showed me how their system is able to reorder materials at the click of a button (in total about 600 SKUs that feed the MMF). The algorithm automatically decides what quantities of said SKUs need to be reordered based on how efficiently they can be packed into a 20-foot container.

As Oleg explained, "Our technology's upside is that at any point, we can go to Home Depot."

Scalability

Many previous attempts at industrialized construction have struggled to scale effectively. Katerra, for instance, grew rapidly but couldn't achieve the efficiency gains needed to make their model work.

Cuby's approach to scaling is more measured and flexible. By using partnerships to expand initially, they can grow their network of MMFs without taking on all the capital risk themselves.

This allows them to prove out their model and refine their processes before fully vertically integrating.

That said, everything is designed with the ability to scale to 275 MMFs in mind.

Economic Cycles

The housing market is notoriously cyclical, which can make it challenging to maintain consistent factory output - a key factor in making prefab construction economically viable.

Cuby's MMF model provides some built-in resilience to market cycles. Because each MMF serves a relatively small geographic area, they can more easily adjust to local market conditions. If demand in one area slows, they can potentially relocate an MMF to a more active market.

Plus, each MMF, given its low capex to launch, requires less throughput to make its economics work. As noted, each MMF will do ~200 single-family homes per year. If you pick most markets in the US, there’s thousands of homes worth of demand. Cuby needs to be a small portion of that demand to make its MMF hum. To add to that, because of Cuby’s approach to labor, they have little fixed labor per MMF, which means they can scale up and scale down with little fixed costs, allowing for dynamic response to market conditions.

Finally, Cuby’s first set of opportunities have an embedded offtaker – a contractually obligated purchaser of the homes at a certain price – reducing risk and positioning each MMF well to take on debt.

There are thousands of other concerns and risks. The system is complex. The market is incredibly hard to crack. Developers are demanding. Cuby needs to build its first US MMF. No one has ever succeeded doing what Cuby plans to do.

At some point, though, you’ve planned for everything that you can and you just need to execute.

That’s where Cuby is now. Over the next 12-15 months, it needs to build its first US MMF, get it to Las Vegas, and partner with Alex and Greg to hire and train an unskilled labor force to build homes cheaper and faster than they can be built otherwise.

Then it needs to do the same thing 274 more times, while maintaining and improving quality, speed, and cost.

Then – 200,000 homes and 100,000 direct jobs in – it will get to start the second phase of its Master Plan.

The Cuby Master Plan

I don’t think I text with anyone more than Aleks at this point. Every day, he sends updates on Cuby’s progress, with pictures and videos from their test MMF.

The other day, he sent me a document titled “Master Plan.” It has three phases:

Phase I: Infrastructure for Scale

Phase II: Kaizen and Further Vertical Integration

Phase III: Direct-to-Consumer Expansion